I thought I would start this as a seperate thread to avoid confusing the B-17 - B-29 Lancaster thread.

Here is some statistics for rear turrets used by the RAf in the Lancaster. I will focus on two at first, the F.N. 20 .303 and the Rose Rice .50 turret for the comparison.

All sources for information and images will be noted where possible. If the thread is in the wrong place or whatever then the Moderators can zap it or move it.

Initial sources are "British Aircraft Armament Vol.1: RAF Gun Turrets", by R Wallace Clarke

The Nash and Thompson Type FN.20 Tail Turret

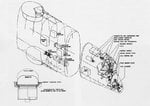

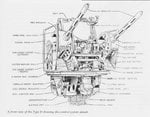

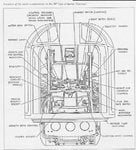

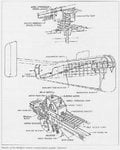

This turret was the most important of the Parnall range, providing rear defence for most of the aircraft of Bomber Command. The designers at Tolworth had been asked to redesign the FN.4, incorporating modifications suggested by Gunnery Leaders on the squadrons. An armoured shield was fitted, and the gunner was provided with a clear-vision panel, but the main improvement was in the ammunition supply. The ammunition boxes in the FN.4 were fitted in the turret under the guns, which limited the supply and affected the trim of the aircraft. A new supply system was devised in which large capacity boxes were fixed to the sides of the rear fuselage, the ammunition belts being taken from the boxes along steel tracks to the base of the turret.

Entering at the base by way of rotating right-angle elbow joints, they were taken through ammunition booster units. These were needed because by the time the belts had reached the guns the weight was far too heavy to be pulled into the breeches by the gun feed mechanisms. The FN servo feed units were an ingenious design in which powered sprockets were automatically energised when the belt pull was more than the gun feeds could handle.

The servo feed unit was driven by a hydraulic motor, two pipes connecting it to the pressure and exhaust lines of the turret feed system. The drive was transferred to the sprockets by four friction clutches. When the guns commenced firing, the belts between the sprockets and the guns tightened, and the platen arms moved across, engaging the clutches. If a belt jammed, an overload device disengaged its clutch. When the obstruction was cleared the clutch could be re-engaged by hand.

Three 9 mm (0.354 in) armour plates, hinged horizontally and moving in unison with the guns in elevation, afforded protection to the gunner's front. The armour affected the gunner's field of view, and also limited the amount of ammunition that could be carried on some long-distance sorties because of its weight. Some Groups decided that rather than set out on a long trip with less than a full supply of ammunition, a better weight-saving idea was to dispense with the armour.

In common with most turrets, when operating at the very low temperatures encountered on night operations, the gunner's view was often restricted by misting and frost glazing the cupola. It was not uncommon for a gunner to smash the Perspex front panel to give a better field of view. Although this added to his physical discomfort it was thought that the clear view was well worth a few degrees' drop in temperature. The removal of the front panel soon became widespread, leading to an official modification to turrets coming off the line at Yate. The front panel was then mounted in side grooves, allowing it to be dropped to give a clear view to the front.

The gunner entered the FN.20 from the fuselage. After clipping his parachute to quick-release hooks just inside the turret, he climbed into his seat and closed the sliding doors behind him, securing the locking catch. On early models of the turret, during violent manoeuvres the catch sometimes gave way, allowing the doors to slide open. Without a backrest the gunner fell back into the fuselage and regained his position only with great difficulty. The catch was redesigned and strengthened.

The turret controls were basically the same as in all Parnall tail turrets, with some modifications.

The triggers on the twin-handled control column operated the four Palmer hydraulically gun-firing valves via Bowden Cables. On some experimental FN.20s used on high-altitude operations, the triggers operated electrical switches controlling relays. The four Browning guns were harmonised to a point 229 m (250 yds) distant on to a 3 m (7ft 6 in) square for night operations, and 366 m (400 yds) on a 2 m (5 ft) square for daylight sorties. The FN.20 turret was popular with gunners, and, apart from the clear-view panel and door catch, few modifications were needed.

All the usual ancillary services were fitted to the turret. Provision was made for observing the angle of drift to assist the navigator, and a more efficient form of oxygen supply was installed. This consisted of an oxygen economiser which regulated the supply to the gunner according to demand. Problems had occurred with the old Type E oxygen masks, and a new mask, Type G, was issued at the time of the introduction of the FN.20. This mask fitted the Type B helmet, and few problems were encountered with the oxygen equipment after this.

The gunner could abandon the aircraft by opening the doors, grabbing and clipping on his parachute, traversing the turret to the beam stops, pulling the pin from his seat harness and falling out backwards. In the event of the gunner being injured, another member of the crew could release the door catch from the fuselage, and there was also a manually operated hydraulic valve outside the turret which enabled the turret to be turned from outside. This facility was added after injured gunners had been trapped inside with fatal consequences. If the hydraulic supply failed, the gunner could turn the turret by disengaging the rotation drive and turning a handle which operated a pinion acting on the gear teeth of the fixed turret ring.

When the Wellington Mk.VI high-altitude bomber was being designed Parnall were asked to provide a pressurised tail turret which was to be known as the Type FN.70, but it was soon found that such a project would need new technology, and the time needed was not available. The Wellington Mk.VI was eventually fitted with a remotely controlled FN.20 turret sighted from a dome in the pressure cabin.

In late 1944 a modified FN.20 was introduced and, as this incorporated new parts, it was designated the Type FN.120. The weight was reduced by 18 kg (40 lb) and some of the main structural members were redesigned. The most popular feature from the gunner's point of view was an improved heating system.

Details of the Type FN.20 Tail Turret

Position in aircraft: Tail

Motive power: Hydraulic motor

Armament: Four 7.7 mm (0.3030 in) Browning Mk.II guns

Ammunition: 2,500 rounds per gun; 1,900 in fuselage boxes, 600 in feed tracks

Ammunition feed: FN hydraulic servo feed from fuselage boxes

Gunsight: Mk.III free mounted reflector sight; Mk.IIC gyro gunsight

Fire control: Palmer electric

Field of view:

Traverse: 94 degrees to each beam

Elevation: 60 degrees

Depression: 45 degrees

Weight of turret (empty): 148 kg (325 lb)

Weight (operational): 614 kg (1,350 lb) = gunner - 82 kg (180 lb); guns - 40 kg (88 lb); ammo - 218 kg (480 lb); boxes - 15 kg (33 lb); tracking - 23 kg (50 lb)

Diameter of ring: (30 1/2 in)

Armour (when fitted): 9 mm (0.354 in) armoured plates to front aspect

Here is some statistics for rear turrets used by the RAf in the Lancaster. I will focus on two at first, the F.N. 20 .303 and the Rose Rice .50 turret for the comparison.

All sources for information and images will be noted where possible. If the thread is in the wrong place or whatever then the Moderators can zap it or move it.

Initial sources are "British Aircraft Armament Vol.1: RAF Gun Turrets", by R Wallace Clarke

The Nash and Thompson Type FN.20 Tail Turret

This turret was the most important of the Parnall range, providing rear defence for most of the aircraft of Bomber Command. The designers at Tolworth had been asked to redesign the FN.4, incorporating modifications suggested by Gunnery Leaders on the squadrons. An armoured shield was fitted, and the gunner was provided with a clear-vision panel, but the main improvement was in the ammunition supply. The ammunition boxes in the FN.4 were fitted in the turret under the guns, which limited the supply and affected the trim of the aircraft. A new supply system was devised in which large capacity boxes were fixed to the sides of the rear fuselage, the ammunition belts being taken from the boxes along steel tracks to the base of the turret.

Entering at the base by way of rotating right-angle elbow joints, they were taken through ammunition booster units. These were needed because by the time the belts had reached the guns the weight was far too heavy to be pulled into the breeches by the gun feed mechanisms. The FN servo feed units were an ingenious design in which powered sprockets were automatically energised when the belt pull was more than the gun feeds could handle.

The servo feed unit was driven by a hydraulic motor, two pipes connecting it to the pressure and exhaust lines of the turret feed system. The drive was transferred to the sprockets by four friction clutches. When the guns commenced firing, the belts between the sprockets and the guns tightened, and the platen arms moved across, engaging the clutches. If a belt jammed, an overload device disengaged its clutch. When the obstruction was cleared the clutch could be re-engaged by hand.

Three 9 mm (0.354 in) armour plates, hinged horizontally and moving in unison with the guns in elevation, afforded protection to the gunner's front. The armour affected the gunner's field of view, and also limited the amount of ammunition that could be carried on some long-distance sorties because of its weight. Some Groups decided that rather than set out on a long trip with less than a full supply of ammunition, a better weight-saving idea was to dispense with the armour.

In common with most turrets, when operating at the very low temperatures encountered on night operations, the gunner's view was often restricted by misting and frost glazing the cupola. It was not uncommon for a gunner to smash the Perspex front panel to give a better field of view. Although this added to his physical discomfort it was thought that the clear view was well worth a few degrees' drop in temperature. The removal of the front panel soon became widespread, leading to an official modification to turrets coming off the line at Yate. The front panel was then mounted in side grooves, allowing it to be dropped to give a clear view to the front.

The gunner entered the FN.20 from the fuselage. After clipping his parachute to quick-release hooks just inside the turret, he climbed into his seat and closed the sliding doors behind him, securing the locking catch. On early models of the turret, during violent manoeuvres the catch sometimes gave way, allowing the doors to slide open. Without a backrest the gunner fell back into the fuselage and regained his position only with great difficulty. The catch was redesigned and strengthened.

The turret controls were basically the same as in all Parnall tail turrets, with some modifications.

The triggers on the twin-handled control column operated the four Palmer hydraulically gun-firing valves via Bowden Cables. On some experimental FN.20s used on high-altitude operations, the triggers operated electrical switches controlling relays. The four Browning guns were harmonised to a point 229 m (250 yds) distant on to a 3 m (7ft 6 in) square for night operations, and 366 m (400 yds) on a 2 m (5 ft) square for daylight sorties. The FN.20 turret was popular with gunners, and, apart from the clear-view panel and door catch, few modifications were needed.

All the usual ancillary services were fitted to the turret. Provision was made for observing the angle of drift to assist the navigator, and a more efficient form of oxygen supply was installed. This consisted of an oxygen economiser which regulated the supply to the gunner according to demand. Problems had occurred with the old Type E oxygen masks, and a new mask, Type G, was issued at the time of the introduction of the FN.20. This mask fitted the Type B helmet, and few problems were encountered with the oxygen equipment after this.

The gunner could abandon the aircraft by opening the doors, grabbing and clipping on his parachute, traversing the turret to the beam stops, pulling the pin from his seat harness and falling out backwards. In the event of the gunner being injured, another member of the crew could release the door catch from the fuselage, and there was also a manually operated hydraulic valve outside the turret which enabled the turret to be turned from outside. This facility was added after injured gunners had been trapped inside with fatal consequences. If the hydraulic supply failed, the gunner could turn the turret by disengaging the rotation drive and turning a handle which operated a pinion acting on the gear teeth of the fixed turret ring.

When the Wellington Mk.VI high-altitude bomber was being designed Parnall were asked to provide a pressurised tail turret which was to be known as the Type FN.70, but it was soon found that such a project would need new technology, and the time needed was not available. The Wellington Mk.VI was eventually fitted with a remotely controlled FN.20 turret sighted from a dome in the pressure cabin.

In late 1944 a modified FN.20 was introduced and, as this incorporated new parts, it was designated the Type FN.120. The weight was reduced by 18 kg (40 lb) and some of the main structural members were redesigned. The most popular feature from the gunner's point of view was an improved heating system.

Details of the Type FN.20 Tail Turret

Position in aircraft: Tail

Motive power: Hydraulic motor

Armament: Four 7.7 mm (0.3030 in) Browning Mk.II guns

Ammunition: 2,500 rounds per gun; 1,900 in fuselage boxes, 600 in feed tracks

Ammunition feed: FN hydraulic servo feed from fuselage boxes

Gunsight: Mk.III free mounted reflector sight; Mk.IIC gyro gunsight

Fire control: Palmer electric

Field of view:

Traverse: 94 degrees to each beam

Elevation: 60 degrees

Depression: 45 degrees

Weight of turret (empty): 148 kg (325 lb)

Weight (operational): 614 kg (1,350 lb) = gunner - 82 kg (180 lb); guns - 40 kg (88 lb); ammo - 218 kg (480 lb); boxes - 15 kg (33 lb); tracking - 23 kg (50 lb)

Diameter of ring: (30 1/2 in)

Armour (when fitted): 9 mm (0.354 in) armoured plates to front aspect