N4521U

Colonel

On my GB53 Lagg3 I had to make part of the ski gas strut from my spares box a bit longer. There are two skis and the struts had to match.

It was just 1mm thick x 2.5mm wide and had to add 1.5mm in length.

A Butt join is not always best speshuly at these dimensions.

Where this method comes from.

Too many years ago I managed to squeeze my way in to the Wood, Fabric and Dope section of A&P school, it's a long story!

We did fabric covering, stitching, repair and spar splices. I had always wanted to work on fabric airplanes is the short of it. So, to my splice.

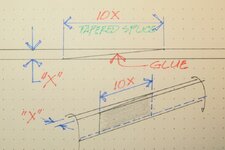

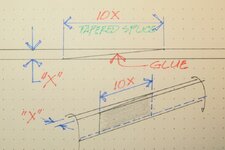

Below is an abbreviated sketch of a spar splice very simplified. Essentially it's a tapered cut along the widest part of the piece.

Basically the taper is 10 times the Thickness of the piece to be spliced and then glued.

For our purposes the longer the taper the better, longer than two eh!!!!! and add plenty of extra for trimming when good and set.

I used a file to make a taper on the strut, then one to match on a strip of white Evergreen so the two pieces were straight and in-line..

When glue is applied and if you try clamping ACROSS the piece with too much pressure it will tend to slide apart.

If you can clamp along the length with Light pressure you'll have more luck with it staying in place.

File, sand to finish, trim to desired length. Easy Peasy!

W

It was just 1mm thick x 2.5mm wide and had to add 1.5mm in length.

A Butt join is not always best speshuly at these dimensions.

Where this method comes from.

Too many years ago I managed to squeeze my way in to the Wood, Fabric and Dope section of A&P school, it's a long story!

We did fabric covering, stitching, repair and spar splices. I had always wanted to work on fabric airplanes is the short of it. So, to my splice.

Below is an abbreviated sketch of a spar splice very simplified. Essentially it's a tapered cut along the widest part of the piece.

Basically the taper is 10 times the Thickness of the piece to be spliced and then glued.

For our purposes the longer the taper the better, longer than two eh!!!!! and add plenty of extra for trimming when good and set.

I used a file to make a taper on the strut, then one to match on a strip of white Evergreen so the two pieces were straight and in-line..

When glue is applied and if you try clamping ACROSS the piece with too much pressure it will tend to slide apart.

If you can clamp along the length with Light pressure you'll have more luck with it staying in place.

File, sand to finish, trim to desired length. Easy Peasy!

W