Some of you might have encountered a problem with incorrect seats for cockpis of your models. Of course there are different rasin part offered and it is no problem to find them via the net for instance. But the cost of a such sets is quite huge often. That's why I would like to show you a way you can make them yourself.

First of all , I would like to emphasize that the final effect depends on you only. The accuracy, your patience and thinking about what you do, are the main factors of that. I think the way is quite easy and all of you can malke their own seats without any troubles

!!! The important note ....please be careful of your hands as the warmed styrene is used. I put chunky gloves used in the kitchen on my hands when making the part. !!!

OK..let's start.

The first step is to make a wooden former. The former dimensions have to be a little bit lesser than the maximal ones of a seat we want to make. I used balsa stick for that. Because I didn't have a square slat I used a round one.Certainly I had to remove some of the wood in order to get the square cross-section. Having it done I marked the central line of the symmetry.

One more thing guys...almost all lines have been drawn by hand. But is it better to use cardboard templates that can be obtained from drawings of any cockpit that are availabe in many books for modellers.I did it because of the time .

To continue..

What templates are needed ? .... the side view, the back view and the top view.Also the front one can come in handy.

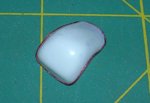

The template of side view has to be retraced on both sides of the wooden slat or block. Then the top view has to be redrawn on the botton of the slat. I would like to make a focus on the fact that the drawing at the bottom presents the inner shape of the mesh of the seat seeing from above. Dimensions of the general top view of a seat determine maximal size of the slat.

I hope these pics below let you understand my English explanation.

First of all , I would like to emphasize that the final effect depends on you only. The accuracy, your patience and thinking about what you do, are the main factors of that. I think the way is quite easy and all of you can malke their own seats without any troubles

!!! The important note ....please be careful of your hands as the warmed styrene is used. I put chunky gloves used in the kitchen on my hands when making the part. !!!

OK..let's start.

The first step is to make a wooden former. The former dimensions have to be a little bit lesser than the maximal ones of a seat we want to make. I used balsa stick for that. Because I didn't have a square slat I used a round one.Certainly I had to remove some of the wood in order to get the square cross-section. Having it done I marked the central line of the symmetry.

One more thing guys...almost all lines have been drawn by hand. But is it better to use cardboard templates that can be obtained from drawings of any cockpit that are availabe in many books for modellers.I did it because of the time .

To continue..

What templates are needed ? .... the side view, the back view and the top view.Also the front one can come in handy.

The template of side view has to be retraced on both sides of the wooden slat or block. Then the top view has to be redrawn on the botton of the slat. I would like to make a focus on the fact that the drawing at the bottom presents the inner shape of the mesh of the seat seeing from above. Dimensions of the general top view of a seat determine maximal size of the slat.

I hope these pics below let you understand my English explanation.

Attachments

Last edited: