Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

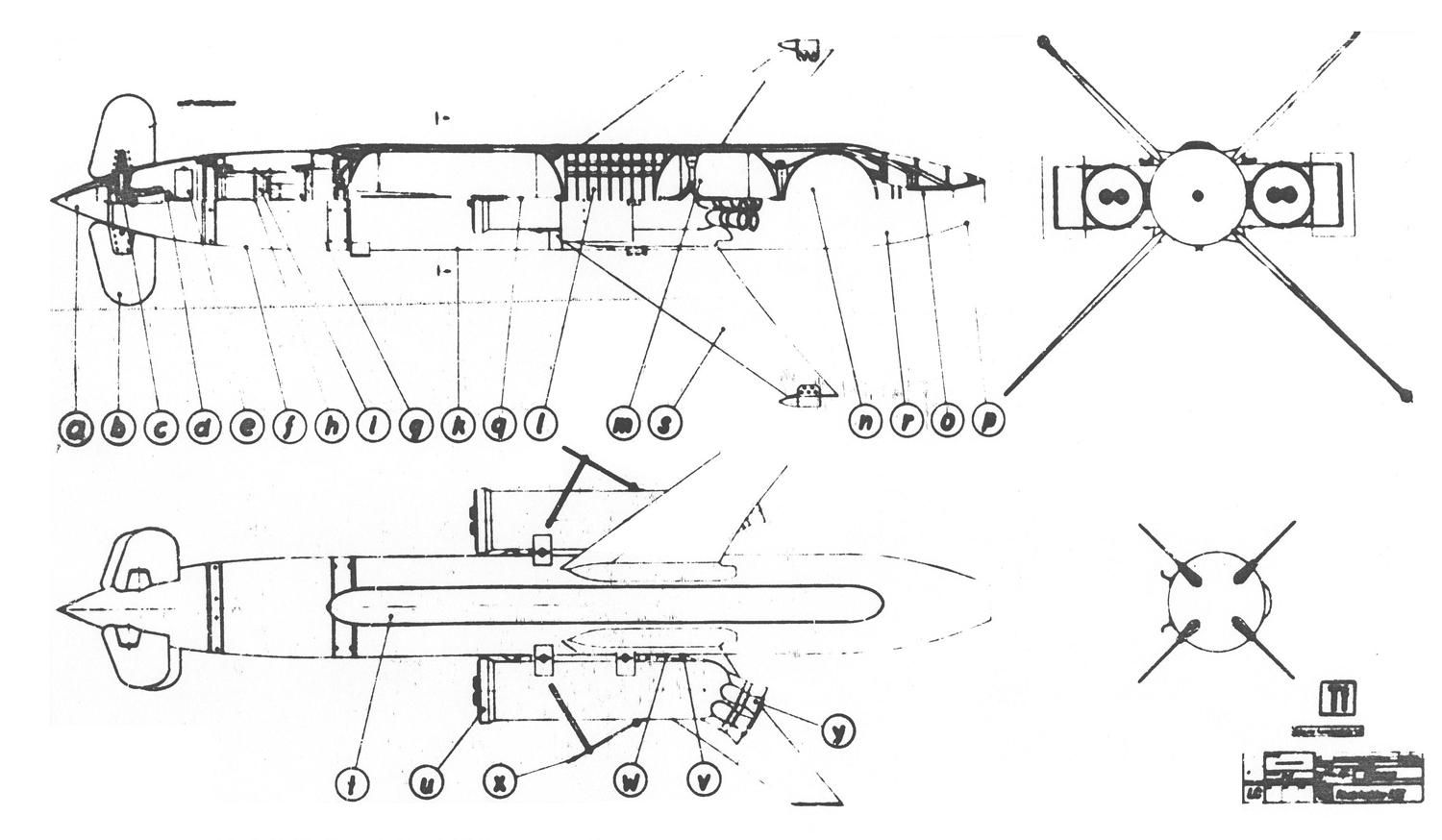

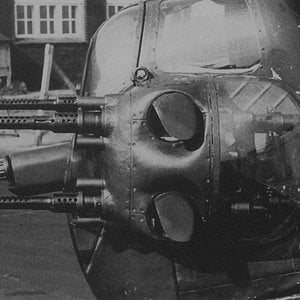

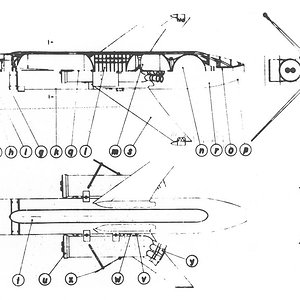

The following is the details of the construction based on the sketch 4 received progressively in the Rhine consequence of the nose to the tail, and that for the R III f The engine of the R III p has in the rest of the same outer shape and the same front, all electrical parts containing Flügkörperhälfte. In the previous section was anticipated that the front half of the fuselage was fully accepted by the device RI. Behind the tip ( a ) housed distance meter, which is covered by a hood made ​​of insulating material, the control head is the rowing machine ( d ), by which the adjustment of the two pairs of oars ( b ) of the two electric motors ( e is made). The steering apparatus is surrounded by a thin-walled body from a molten alloy and has the bearing for supporting the front of the two mutually perpendicular axes plug ( c ), the stub projecting from the housing. The individual pairs of oars can be connected with one pass screw in a simple way with the axes. The center housing (includes the control button f ) for the electrical components.

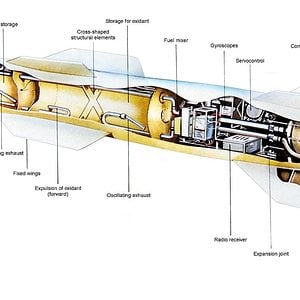

The receiver, the batteries ( g ), the converters and the gyro-based ( i ) for the K-control ( rate control ) are in an installation frame ( h elastically suspended). As already mentioned, the R III has no ailerons. The following section referred to below in " Rheinmetall-Borsig control "ensures that regardless of the particular value of the commanded roll angle of the steering Protect transverse force is maintained. In the structural design of the front housing part has been placed on easy replacement of individual groups and all parts of the device value and savings substances largely replaced by steel. The largest part of the hull again take the components of a cruise engine. Wherein R 3 f and liquid components Visol (be diesel oil ), sage ( nitric acid ) is used. Press under pressure they go into the oven and incinerated, and their gaseous Verbrennungsproduckte occur at high velocity through the nozzle of the combustion chamber and enter the recoil force on the power.

The tank weights of both components are 336 kg and 89 kg sage Visol. When pressed air 18 kg of nitrogen are also required. In the design of the march engine focuses hikes were to keep the entire device during the emptying of the tank as small as possible to maintain the constancy of stability. This requirement out the order of the engine parts found: At the front is the flanged directly to the center housing of the steering member sage container (k) closely followed by the double chamber housing, the front chamber ( l ) carries the Brandsplitterlaborierung, while the rear half ( m ) the Visol receives. This is followed by the ball (excludes n ) for the compressed air to. The last part of the engine is the combustion chamber ( o ) to the nozzle. A thin cover plate ( p ) of paraholischer outer mold lined combustion chamber and completes the keeper, so that the aerodynamic shape of the hull. For emptying the tank of its upper half Gass pressure (nitrogen) is supplied, while the interior sides a respective pivotable trunk ( q ) of the ball-shaped part remains. The proboscis subject to the same acceleration as the fluids and therefore always immersed in the liquid. The thrust remains constant during the first 25 s at 1700 kg, and increases from there on up to the 45th Second to about 2300 kg. This operation is a special reducer ( r achieved) that the internal gas pressure in the tanks to 25 atm kontant holding and later increasing to 33 atm. The sage carries in a thin aluminum container shirt as lining, thus ensuring a shelf life of half a year. Are all the other parts that are constantly in contact with the nitric acid, made ​​of pure aluminum for the same reason: only the elastic member of the pivotal proboscis consists of a corrugated metal tube of V 2 A steel. The top of the tank to the combustion chamber pipes are directly behind the tanks, air and water-tight by crushing thin slats: the open only after the inflow of compressed gas ( nitrogen ), which is destroyed by its pressure the crushing plates. To standardize the pipes and fittings of the same cross-section is used for all lines: the larger flow of sage is supported by 3 array of pipes account.

The outer wall of the two-chamber body is stiffened by a welded-rings: she wears outside to accommodate the half-wings each with 2 welded-on guide rails, in which the wing base is inserted and secured by a screw. The wing ( S ) consist of Lignfolholz ( In a large series of relevant R III plywood should by the planners in place of Lignofolholzes due to the tight phenol-based to be used! ). Subsequent to the double chamber housing pressurized gas through elastic ball is bolted flange connections with the bottom of Visoltanks. It consists of two in the middle welded together hemispherical shells made ​​of thin sheet steel and is filled with 250 atm of nitrogen. The compressed gas passes through a short pipe into the reducer. The ignition of the cruise engine is carried out by coiling of the reducing valve, after which the compressed gas flows into the container and urges the two components into the furnace. All piping and cable channels are provided on top of de hull along and are covered by the hull shape well-adapted cable channel.

Under the sage and the two-chamber container housing is ever a tab welded in the front and rear of the shoe can hook so that after the start of the guide shoes dissolve independently from the body.

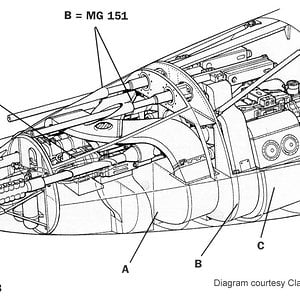

When using the term powder in place of the engine drive liquid, the total structure of the R III changes only slightly. In the front steering member aun now closes the combustion chamber and forms the main part of the cylindrical body. This chamber is the front to the laboring completed by a screw cap. The ignition of the charge ( 450 kg Diglykolpulver ) by an additional cargo Sonderzündschraube a coarse black powder. Wall thickness, shape, and insulating bars of the powder are selected so that a virtually constant thrust profile with a burn time of about 50 s is. The combustion gases flow out of 4 thrusters, which project obliquely backward from the rear bumper. The rear part of the cell is again a panel of paraholischer outer shape, which is pushed from behind on the load and fixed to the combustion chamber. The payload itself consists of a cylindrical sheet metal jacket Brandsplitterlaborierung with a total weight of 150 kg. There are 60 kg incendiary fragmentation, arranged in three concentric rings, with a total number of 1700 pieces splitter. The firing tests have shown that in this arrangement, for the destruction of a B 17 / B 24-splitter sufficient density of 0.3 is achieved even at 35 m.

The units III R f and R p III can be started in the same way by means of two right and left of the hull between the fixed inclined vanes basic actuators. These are secured by a respective nominal breaking screw that had a breaking strength for the normal, that occur during transport and loading the gun carriage to impact. However, they are sheared off at the beginning of the starting acceleration, followed by lugs (v) to the combustion chambers in corresponding shoes ( w lay) of the body and transmit the thrust to the overall launch body. The launchers are no longer available now firmly connected to the hull and the outwardly directed lateral forces of the two output areas (after burnout under the action x ) so torn from the flight rocket that no contact with the trunk or the structure may occur. The start combustion chambers are made ​​of steel pipes of 320 mm diameter and 7 mm wall thickness, which are completed by a rear welded steel floor and front by a aufgeschraubbaren cover. The axes of the nozzles ( y ) directed to the center of gravity of the whole body in order to prevent a torque from uneven finish. The weight of the two booster rockets laborierten is 390 kg of which 170 kg ( Diglycol powder-profile accounts) on the charge. You give the R III within 1 s an initial velocity of 200 m / s with a thrust of 25,000 kg / s

The receiver, the batteries ( g ), the converters and the gyro-based ( i ) for the K-control ( rate control ) are in an installation frame ( h elastically suspended). As already mentioned, the R III has no ailerons. The following section referred to below in " Rheinmetall-Borsig control "ensures that regardless of the particular value of the commanded roll angle of the steering Protect transverse force is maintained. In the structural design of the front housing part has been placed on easy replacement of individual groups and all parts of the device value and savings substances largely replaced by steel. The largest part of the hull again take the components of a cruise engine. Wherein R 3 f and liquid components Visol (be diesel oil ), sage ( nitric acid ) is used. Press under pressure they go into the oven and incinerated, and their gaseous Verbrennungsproduckte occur at high velocity through the nozzle of the combustion chamber and enter the recoil force on the power.

The tank weights of both components are 336 kg and 89 kg sage Visol. When pressed air 18 kg of nitrogen are also required. In the design of the march engine focuses hikes were to keep the entire device during the emptying of the tank as small as possible to maintain the constancy of stability. This requirement out the order of the engine parts found: At the front is the flanged directly to the center housing of the steering member sage container (k) closely followed by the double chamber housing, the front chamber ( l ) carries the Brandsplitterlaborierung, while the rear half ( m ) the Visol receives. This is followed by the ball (excludes n ) for the compressed air to. The last part of the engine is the combustion chamber ( o ) to the nozzle. A thin cover plate ( p ) of paraholischer outer mold lined combustion chamber and completes the keeper, so that the aerodynamic shape of the hull. For emptying the tank of its upper half Gass pressure (nitrogen) is supplied, while the interior sides a respective pivotable trunk ( q ) of the ball-shaped part remains. The proboscis subject to the same acceleration as the fluids and therefore always immersed in the liquid. The thrust remains constant during the first 25 s at 1700 kg, and increases from there on up to the 45th Second to about 2300 kg. This operation is a special reducer ( r achieved) that the internal gas pressure in the tanks to 25 atm kontant holding and later increasing to 33 atm. The sage carries in a thin aluminum container shirt as lining, thus ensuring a shelf life of half a year. Are all the other parts that are constantly in contact with the nitric acid, made ​​of pure aluminum for the same reason: only the elastic member of the pivotal proboscis consists of a corrugated metal tube of V 2 A steel. The top of the tank to the combustion chamber pipes are directly behind the tanks, air and water-tight by crushing thin slats: the open only after the inflow of compressed gas ( nitrogen ), which is destroyed by its pressure the crushing plates. To standardize the pipes and fittings of the same cross-section is used for all lines: the larger flow of sage is supported by 3 array of pipes account.

The outer wall of the two-chamber body is stiffened by a welded-rings: she wears outside to accommodate the half-wings each with 2 welded-on guide rails, in which the wing base is inserted and secured by a screw. The wing ( S ) consist of Lignfolholz ( In a large series of relevant R III plywood should by the planners in place of Lignofolholzes due to the tight phenol-based to be used! ). Subsequent to the double chamber housing pressurized gas through elastic ball is bolted flange connections with the bottom of Visoltanks. It consists of two in the middle welded together hemispherical shells made ​​of thin sheet steel and is filled with 250 atm of nitrogen. The compressed gas passes through a short pipe into the reducer. The ignition of the cruise engine is carried out by coiling of the reducing valve, after which the compressed gas flows into the container and urges the two components into the furnace. All piping and cable channels are provided on top of de hull along and are covered by the hull shape well-adapted cable channel.

Under the sage and the two-chamber container housing is ever a tab welded in the front and rear of the shoe can hook so that after the start of the guide shoes dissolve independently from the body.

When using the term powder in place of the engine drive liquid, the total structure of the R III changes only slightly. In the front steering member aun now closes the combustion chamber and forms the main part of the cylindrical body. This chamber is the front to the laboring completed by a screw cap. The ignition of the charge ( 450 kg Diglykolpulver ) by an additional cargo Sonderzündschraube a coarse black powder. Wall thickness, shape, and insulating bars of the powder are selected so that a virtually constant thrust profile with a burn time of about 50 s is. The combustion gases flow out of 4 thrusters, which project obliquely backward from the rear bumper. The rear part of the cell is again a panel of paraholischer outer shape, which is pushed from behind on the load and fixed to the combustion chamber. The payload itself consists of a cylindrical sheet metal jacket Brandsplitterlaborierung with a total weight of 150 kg. There are 60 kg incendiary fragmentation, arranged in three concentric rings, with a total number of 1700 pieces splitter. The firing tests have shown that in this arrangement, for the destruction of a B 17 / B 24-splitter sufficient density of 0.3 is achieved even at 35 m.

The units III R f and R p III can be started in the same way by means of two right and left of the hull between the fixed inclined vanes basic actuators. These are secured by a respective nominal breaking screw that had a breaking strength for the normal, that occur during transport and loading the gun carriage to impact. However, they are sheared off at the beginning of the starting acceleration, followed by lugs (v) to the combustion chambers in corresponding shoes ( w lay) of the body and transmit the thrust to the overall launch body. The launchers are no longer available now firmly connected to the hull and the outwardly directed lateral forces of the two output areas (after burnout under the action x ) so torn from the flight rocket that no contact with the trunk or the structure may occur. The start combustion chambers are made ​​of steel pipes of 320 mm diameter and 7 mm wall thickness, which are completed by a rear welded steel floor and front by a aufgeschraubbaren cover. The axes of the nozzles ( y ) directed to the center of gravity of the whole body in order to prevent a torque from uneven finish. The weight of the two booster rockets laborierten is 390 kg of which 170 kg ( Diglycol powder-profile accounts) on the charge. You give the R III within 1 s an initial velocity of 200 m / s with a thrust of 25,000 kg / s