Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Allison v-1710 Engine Life

- Thread starter MakerDude

- Start date

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

More options

Who Replied?ThomasP

Chief Master Sergeant

Per the list posted above by ddwhitney, the Packard V-1650-1 (~RR Merlin XX) had a TBO of 400 hrs while the V-1710 had a TBO of 500 hrs - so the answer to your question is yes - at least as of the list dated November 1943.

BarnOwlLover

Staff Sergeant

Given how durable the single stage Allisons were during World War II, that makes the issues that the F-82s had with the two stage versions all the more regrettable IMO. Also given how much the RAF loved to overboost the Allisons in their Mustangs that were used for recon with seemingly few adverse effects (and quite a while before they were running similar boost levels on the Merlin--and they we're running 25 lbs boost/80" on Mustang IIIs before it was approved by the USAAF and Packard, and even before Rolls-Royce approved it for common practice on Spitfire IXs and Mosquitoes when those were also used to intercept V-1s along side the Mustang IIIs).

GregP

Major

The Allison is a much tougher engine than the Merlin. Today, racing "Merlins" mostly use Allison rods because they are stronger.

But, before I hear the Merlin fan screams, the Merlin was a very good engine at stock power levels. You have to pump it up over 2,500 hp before the stock Merlin rods begin to give trouble. In wartime, they set the TBO so that 99% of the engine blocks could be overhauled when the time came. It had nothing to do with how the engine ran ...it was all down to the percent fallout at overhaul. Today, in service, they both give very good TBO, and both ran well right up to TBO in military service ... mostly.

In wartime, there is not much difference between 400 and 500 hours. Both give good service. Let's say you flew a 5-hour mission every other day and a 3 hour mission half as often between the 5 hour missions. You'd reach 400 hours in about 4 months of operation time and 500 hours in about 5 months. It takes fewer hours to overhaul an Allison, but it takes about the same amount of time to change an Allison as it does to change a Merlin. So, as far as the operational units were concerned, as long as the depot had an overhauled engine when it was needed, the time for actual engine overhaul was not a factor. Might be if the depot was out of completed, overhauled engines, but they generally weren't.

If you are flying piston fighters, a crew chief can't really complain if an engine change is needed every 4 or 5 months. That's decent wartime service. In peacetime, an engine might last a year and half between overhauls because budgets are smaller in peacetime and flying hours are reduced. So is proficiency.

Both gave very acceptable, reliable service once the issues were worked out. It took a bit longer to work out the Allison issues because duplicating the problem on a test stand in Indianapolis, Indiana wasn't always easy. They wasted 5 months or so before they found out that British fuel was mixed differently from U.S. fuel. It wasn't better or worse, it was different. Once the carb jets were changed, that went away. Along the way, the intake issue also had to be solved. One of the issues with the P-38 in Europe was the cockpit heater. That was NOT an Allison issue.

The Merlin had issues, too, but they didn't have the fuel issue because they were correctly jetted for the fuel to start with. The factory was also a LOT closer than the Allison factory was. That tends to make things easier. There is a reason why local resources are easier to deal with.

Basically, the two engines were about a wash, service-wise, once sorted. The Merlin was the better engine at higher altitude (that is; more power at altitude) once it got a 2-stage supercharger, but the turbo system in the P-38 was also good ... again, AFTER it was sorted out, and would fly about as high as a contemporary Merlin would.

I've talked with two pilots who flew F-82s with Allisons. One loved it and one said he had engine issues. This was the end of the piston era and everyone was wanting jets, so not a lot of effort was expended to sort the Allisons that showed problems. Instead, they got jets quicker they they otherwise would have.

But, before I hear the Merlin fan screams, the Merlin was a very good engine at stock power levels. You have to pump it up over 2,500 hp before the stock Merlin rods begin to give trouble. In wartime, they set the TBO so that 99% of the engine blocks could be overhauled when the time came. It had nothing to do with how the engine ran ...it was all down to the percent fallout at overhaul. Today, in service, they both give very good TBO, and both ran well right up to TBO in military service ... mostly.

In wartime, there is not much difference between 400 and 500 hours. Both give good service. Let's say you flew a 5-hour mission every other day and a 3 hour mission half as often between the 5 hour missions. You'd reach 400 hours in about 4 months of operation time and 500 hours in about 5 months. It takes fewer hours to overhaul an Allison, but it takes about the same amount of time to change an Allison as it does to change a Merlin. So, as far as the operational units were concerned, as long as the depot had an overhauled engine when it was needed, the time for actual engine overhaul was not a factor. Might be if the depot was out of completed, overhauled engines, but they generally weren't.

If you are flying piston fighters, a crew chief can't really complain if an engine change is needed every 4 or 5 months. That's decent wartime service. In peacetime, an engine might last a year and half between overhauls because budgets are smaller in peacetime and flying hours are reduced. So is proficiency.

Both gave very acceptable, reliable service once the issues were worked out. It took a bit longer to work out the Allison issues because duplicating the problem on a test stand in Indianapolis, Indiana wasn't always easy. They wasted 5 months or so before they found out that British fuel was mixed differently from U.S. fuel. It wasn't better or worse, it was different. Once the carb jets were changed, that went away. Along the way, the intake issue also had to be solved. One of the issues with the P-38 in Europe was the cockpit heater. That was NOT an Allison issue.

The Merlin had issues, too, but they didn't have the fuel issue because they were correctly jetted for the fuel to start with. The factory was also a LOT closer than the Allison factory was. That tends to make things easier. There is a reason why local resources are easier to deal with.

Basically, the two engines were about a wash, service-wise, once sorted. The Merlin was the better engine at higher altitude (that is; more power at altitude) once it got a 2-stage supercharger, but the turbo system in the P-38 was also good ... again, AFTER it was sorted out, and would fly about as high as a contemporary Merlin would.

I've talked with two pilots who flew F-82s with Allisons. One loved it and one said he had engine issues. This was the end of the piston era and everyone was wanting jets, so not a lot of effort was expended to sort the Allisons that showed problems. Instead, they got jets quicker they they otherwise would have.

Deleted member 68059

Staff Sergeant

- 1,056

- Dec 28, 2015

The Allison is a much tougher engine than the Merlin. Today, racing "Merlins" mostly use Allison rods because they are stronger.

You might consider rephrasing that as:

"Racing Merlin's often use Allison rods because the Allison rods are stronger"

... because I`ve never heard of a single other V-1710 part being used in any racing Merlin.

BarnOwlLover

Staff Sergeant

All I know is that I've read several sources (including Ed Schmued's condemnation of the engine) that the Allisons in the F-82s weren't popular with pilots or mechanics because of frequent supercharger/induction related issues. Also spark plug changes were frequent (the latter not exclusive to the Allison when run on 145 octane fuel--even Merlins needed more plug changes on that fuel vs 130 octane due to added lead).

Of course, as hinted, Allison and GM had little incentive to fix the issue because jets were on the way and the F-82s were place holders for long range jet fighters and jet night/AW interceptors (though those jets were often delayed--hence the F-82's service in the Korean War). That said, I don't think that would've flown during World War II if Allison was the exclusive source of V-12 engines.

But I also don't think that Allison had much incentive to develop a two stage supercharged V-1710 due to no serious USAAF orders, and the existence of the Packard Merlin. And even that was possible largely due to British/Commonwealth need for an other source for Merlins, and the Air Ministry arm-twisting Rolls-Royce into suspending the $6000 per engine licensing fee provided that a certain percentage of production went to British or Commonwealth aircraft.

Which I think also sucked given that the Allison should've been a great engine supercharger design aside, as it was cheaper and simpler to make, and had pent-roof/hemispherical combustion chambers before that became common even high performance automotive engines.

Of course, as hinted, Allison and GM had little incentive to fix the issue because jets were on the way and the F-82s were place holders for long range jet fighters and jet night/AW interceptors (though those jets were often delayed--hence the F-82's service in the Korean War). That said, I don't think that would've flown during World War II if Allison was the exclusive source of V-12 engines.

But I also don't think that Allison had much incentive to develop a two stage supercharged V-1710 due to no serious USAAF orders, and the existence of the Packard Merlin. And even that was possible largely due to British/Commonwealth need for an other source for Merlins, and the Air Ministry arm-twisting Rolls-Royce into suspending the $6000 per engine licensing fee provided that a certain percentage of production went to British or Commonwealth aircraft.

Which I think also sucked given that the Allison should've been a great engine supercharger design aside, as it was cheaper and simpler to make, and had pent-roof/hemispherical combustion chambers before that became common even high performance automotive engines.

Last edited:

Shortround6

Lieutenant General

I would check out that statement very carefully. Pent roof and hemispherical combustion chambers are NOT the same. The hemispherical combustion chamber dates back to at least 1913 in Peugeot Grand Prix car and pent roof chambers (or at least angle valve heads) were used in several WW I aircraft engines. A 4 valve head using angled valves was used in the Mercedes 18/100 4.5 liter 1914 Grand Prix engine and was not the first 4 valve automotive engine.and had pent-roof/hemispherical combustion chambers before that became common even high performance automotive engines.

There are a lot of websites and magazine articles and books that claim that post WW II advances in auto engines were a result of work done in WW II. Most are bullsh*t.

Most think that the Ford flat head was the height of automotive technology until the early 1950s.

Deleted member 68059

Staff Sergeant

- 1,056

- Dec 28, 2015

There is a lot of truth in that, however, the devil is in the detail, and the pent roof 16valve head only REALLY started to work properly once the ports were sorted to get tumble and the piston>chamber geometry was sorted to get the squish working. I`ve never seen any car cylinder head get all those details right until the Cosworth DFV, although I "believe" that it was probably managed first in 1950`s motorcycles, the V-1710 almost got it but I think the squish zones were far too small, and the squish gap too big to hit the money. Squish gap is one of those things where "nearly right" is worse than none at all in many cases.I would check out that statement very carefully. Pent roof and hemispherical combustion chambers are NOT the same. The hemispherical combustion chamber dates back to at least 1913 in Peugeot Grand Prix car and pent roof chambers (or at least angle valve heads) were used in several WW I aircraft engines. A 4 valve head using angled valves was used in the Mercedes 18/100 4.5 liter 1914 Grand Prix engine and was not the first 4 valve automotive engine.

View attachment 734821

There are a lot of websites and magazine articles and books that claim that post WW II advances in auto engines were a result of work done in WW II. Most are bullsh*t.

Most think that the Ford flat head was the height of automotive technology until the early 1950s.

View attachment 734822

Shortround6

Lieutenant General

I have always wondered about the Bristol 4 valve radials. An angle combustion chamber but one intake valve in each "flat" and one exhaust valve in each "flat" which would put paid to the whole cross flow idea unless there was some weird turbulence/swirl going on, but I am surely not expert enough to even begin to guess.

The engine makers had the test instruments, such as they were back then and I generally figure (Bristol and sleeve valves aside) that they had good reasons for doing what they did, some of which had little to do with peak power but sometimes a lot to do with size/weight/ease of production.

I also don't know how the gas flows (cubic ft per second) work when going from a large slow revving engine to a small high revving engine and what supercharging does to the system, if anything.

I just get annoyed when some car fan spouts off about how brand XXX was so smart to use the combustion chamber design (or other feature) from a WW II aircraft engine in the 1950s when the aircraft engine maker was copying a WW I or before design.

No engine designer of the 1930s worth his T square could have been ignorant of the Grand Prix engines of the pre WW I and post WW I period. He might have had different goals (cheap, low powered engine) but he would have been keeping up with design and material advancement for either improvements or for the next design.

The engine makers had the test instruments, such as they were back then and I generally figure (Bristol and sleeve valves aside) that they had good reasons for doing what they did, some of which had little to do with peak power but sometimes a lot to do with size/weight/ease of production.

I also don't know how the gas flows (cubic ft per second) work when going from a large slow revving engine to a small high revving engine and what supercharging does to the system, if anything.

I just get annoyed when some car fan spouts off about how brand XXX was so smart to use the combustion chamber design (or other feature) from a WW II aircraft engine in the 1950s when the aircraft engine maker was copying a WW I or before design.

No engine designer of the 1930s worth his T square could have been ignorant of the Grand Prix engines of the pre WW I and post WW I period. He might have had different goals (cheap, low powered engine) but he would have been keeping up with design and material advancement for either improvements or for the next design.

GregP

Major

Hi Callum. OK, I can rephrase that.You might consider rephrasing that as:

"Racing Merlin's often use Allison rods because the Allison rods are stronger"

... because I`ve never heard of a single other V-1710 part being used in any racing Merlin.

You don't have to torque the heads every 25 hours on an Allison. You do on a Merlin. A Merlin has something like 13,500 parts. A large number of those parts are nuts, washers, and bolts. An Allison has about 7,000 parts. So, working on an Allison results in torquing a LOT less bolts. The Allison holds a tune longer than a Merlin. That from talking with operators both during the war and today. I believe that and have seen it in action. Merlin birds get more engine-tweaking than Allison birds do from 16 years of personal observation of wearbird operations. I personally know one guy with 1,100 hours on his Allison and it is running just fine. The highest-time Merlin I know of personally is around 750 - 800 hours. There is nothing to say the Merlin won't reach the same level other than speculation.

That being said, there is absolutely nothing wrong with a Merlin. Great engines. As a family, they certainly contributed more than Allison-powered birds did in total to the war effort. They do take a bit more maintenance and also take quite a bit longer to overhaul. Again, that is not a knock, just operational reality. Both start, run, and continue to run just fine in general service. An Allison might leak a bit less oil than a Merlin in general. That is subjective; just observation. If I had the money for a warbird, it would likely be a Merlin-powered bird because of the aircraft I like, not because of the engine. In service, if you have the money to fly a warbird, both run quite well.

But, if I had the choice, I'd fly a Spitfire or a P-51 over a P-39 or P-40 any day of the week. Again, if money were no issue, I might choose a P-38 and disable the turbos, if for no other reason than I like P-38s. A Spitfire IX or P-51D would be mighty hard to turn down, though. Both are wonderful to contemplate.

If I were filthy rich and could afford a crew, a radial-powered bird might be great. If it was just me, I'd take a V-12.

WAY less oil to wipe off the airplane after flying!

ThomasP

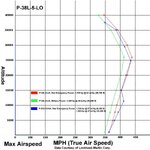

I also have not come across any reports of P-38 engines being operated at greater than 60" of MP, but on page 72 of the P-38 pilot manual, there is a graph that shows 62" of MP at 3000 rpm

Pilots Manual Lockheed P-38 Lightning Pilot Training Manual (3).pdf

The attached chart shows the speed of a P-38L-5 at 64" MP. (note, weight and rpm not given) Now, if these MP's were used operationally or not, I do not know. I have read of pilots on pre P-38J models running their engines above the maximum MP's given in the manuals.

FWIW

Eagledad

I also have not come across any reports of P-38 engines being operated at greater than 60" of MP, but on page 72 of the P-38 pilot manual, there is a graph that shows 62" of MP at 3000 rpm

Pilots Manual Lockheed P-38 Lightning Pilot Training Manual (3).pdf

The attached chart shows the speed of a P-38L-5 at 64" MP. (note, weight and rpm not given) Now, if these MP's were used operationally or not, I do not know. I have read of pilots on pre P-38J models running their engines above the maximum MP's given in the manuals.

FWIW

Eagledad

Attachments

BarnOwlLover

Staff Sergeant

As far as road car engines go, a lot of that tech that was used on aircraft engines or racing engines didn't become common place until after World War II. High end sports cars like top of the line Alfa Romeos and Bugattis had DOHC (albeit usually two valve) heads (and most World War II inline engines were SOHC, but four valve). Yes, the early Peugeot Indy Cars/GP cars had DOHC/4 valve heads since before World War I, but those were racing cars, not road vehicles. Such things only started to become common in "bread and butter" European and Japanese cars in the '60s and '70s, and significantly longer on American cars (the Ford Pinto engine being an obvious exception).

Turbochargers did come from World War II (as far as being perfected for aero use), but superchargers had been around for much longer than that. Of course, the advent of racing turbos did breath (literally) new life into the Offenhauser Indy Car engine (which owes a bit of its heritage to the old Peugeot engine), because it could run higher boost levels more reliably than other engines could (until limits were imposed by USAC after 1973) because of its heads being integral to the block. Even most World War II aviation V-12s had separate heads, cylinder blocks and crankcases.

Turbochargers did come from World War II (as far as being perfected for aero use), but superchargers had been around for much longer than that. Of course, the advent of racing turbos did breath (literally) new life into the Offenhauser Indy Car engine (which owes a bit of its heritage to the old Peugeot engine), because it could run higher boost levels more reliably than other engines could (until limits were imposed by USAC after 1973) because of its heads being integral to the block. Even most World War II aviation V-12s had separate heads, cylinder blocks and crankcases.

Dam phone..As far as I am aware, no V-1710-93 was ever fitted to the P-38.

Also as far as I am aware, no war-time V-1710 fitted to the P-38 was ever operationally rated over 1600 BHP at 3000 rpm at 60"Hg - WER or otherwise - using 130 grade fuel.

The -93 was fitted to the P-63A/C but was never operationally rated at 1800 BHP and 75"Hg.

Even post-war, the V-1710-140 series (~improved -93) fitted to the F-82E/F/G - with 115/145 grade fuel - had to use ADI to achieve 74"Hg in WER. They tried higher ratings than 3200 rpm at 65"Hg without ADI but the engines kept blowing their intake manifolds off and/or destroying pistons & rods.

F-82E restrictions - maneuver, loads, and engine using 115/145 grade fuel - from 1948

The F29 and F30 were rated for 1725 at 3200rpm. It wasn't used in service because the tip speed was too high on the propellers. This was a problem for many US aircraft. The P-47D with paddle blade propellers and the B-25 were both fast at lower rpm. Late war and post war manuals for the B-25 don't bother with listing mil power settings for this reason.

Last edited:

GregP

Major

The V-1710-93 could never have been fitted to a P-38. It is an E-Series engine, engineered to operate with a driveshaft and remote propeller gearbox.

I don't know of any WWII V-12 that operated at over 65" MAP without ADI. Do you?

Joe Yancey built up a hybrid V-1710 using a G-series power section and nose case mated to an F-Series accessory section with an adapter. He ran it at Reno in the Yak "Full Noise" at 110" and it ran great. They won Bronze, won Silver, and went to the stock Allison for the gold, finishing next to last on a stock engine. Joe's hybrid racing V-1710 still runs great today. It suffered no damage in the racing and was putting out about 2,100 hp.

I don't know of any WWII V-12 that operated at over 65" MAP without ADI. Do you?

Joe Yancey built up a hybrid V-1710 using a G-series power section and nose case mated to an F-Series accessory section with an adapter. He ran it at Reno in the Yak "Full Noise" at 110" and it ran great. They won Bronze, won Silver, and went to the stock Allison for the gold, finishing next to last on a stock engine. Joe's hybrid racing V-1710 still runs great today. It suffered no damage in the racing and was putting out about 2,100 hp.

Deleted member 68059

Staff Sergeant

- 1,056

- Dec 28, 2015

A Merlin has something like 13,500 parts. A large number of those parts are nuts, washers, and bolts. An Allison has about 7,000 parts. So, working on an Allison results in torquing a LOT less bolts.

I`ve heard this many times, and I`m afraid I dont believe it, and I have never once seen any evidence for either figure (I`m sure the 7000 is true, but I dont think

any supercharged aero V12 will have a parts count varying by more than about 25% to any other, what on earth could they be ?, surely this is

something like one person counting each carburettor jet and magneto winding wire, and the other person ignoring all the ancillaries)

Even if each bolt had an extra lock pin and washer it would not amount to more than a few hundred bits.

Until someone takes both engines to bits and films it, and counts the bits - this one is firmly in the "myths" basket for me. I dont know, maybe if you

picked a fuel injected two-stage 1946 Merlin-100 and the very first V-1710 ever made in 1930... but like-for-like, no way.

As you will see in my book, generally speaking in terms of the basic engine architecture, I rate the V-1710 more modern than the Merlin.

Last edited:

BarnOwlLover

Staff Sergeant

Merlin 60 series engines ran up to 25 PSI boost/81" HG in Mustang IIIs used by the RAF for V-1 interceptions, and Merlin 25s in Mosquitos for the same duty. This was also approved late war for the V-1650-7. The RAF also ran Allisons to 70" in Mustang Is and IIs used for tactical recon. Merlin 100s ran to 25 lbs boost without ADI. Anything over 81"/25 lbs pretty much needed ADI. Those were WEP/combat power figures, and the Merlin 100 were designed for 18 lbs boost (67") sustained rated power. V-1650-9 ran up to 90", but with ADI (rated for 80-81" dry). Rolls-Royce and the RAF were playing with anything from 18 lbs to 25 lbs boost during 1943 into '44 on Spitfires and Mustangs.

There's various reports citing this at World War II Aircraft Performance in the Mustang section and Spitfire IX section.

Note that these were combat/WEP figures, not sustained until the Merlin 100 was cleared for 18 lbs sustained. I believe that the Griffon was also ultimately approved for 18-25 lbs boost for WEP/combat by war's end.

The G-series V-1710s in the F-82s needed ADI for anything much over 61" from what I've read, mostly because of supercharger/induction induced detonation issues that Allison never fixed in period (NAA and the USAAF tried to themselves, but Allison and GM ignored them).

There's various reports citing this at World War II Aircraft Performance in the Mustang section and Spitfire IX section.

Note that these were combat/WEP figures, not sustained until the Merlin 100 was cleared for 18 lbs sustained. I believe that the Griffon was also ultimately approved for 18-25 lbs boost for WEP/combat by war's end.

The G-series V-1710s in the F-82s needed ADI for anything much over 61" from what I've read, mostly because of supercharger/induction induced detonation issues that Allison never fixed in period (NAA and the USAAF tried to themselves, but Allison and GM ignored them).

SaparotRob

Unter Gemeine Geschwader Murmeltier XIII

Those parts were required for the proper installation of the Flying Lady.I`ve heard this many times, and I`m afraid I dont believe it, and I have never once seen any evidence for either figure (I`m sure the 7000 is true, but I dont think

any supercharged aero V12 will have a parts count varying by more than about 25% to any other, what on earth could they be ?, surely this is

something like one person counting each carburettor jet and magneto winding wire, and the other person ignoring all the ancillaries)

Even if each bolt had an extra lock pin and washer it would not amount to more than a few hundred bits.

Until someone takes both engines to bits and films it, and counts the bits - this one is firmly in the "myths" basket for me. I dont know, maybe if you

picked a fuel injected two-stage 1946 Merlin-100 and the very first V-1710 ever made in 1930... but like-for-like, no way.

ThomasP

Chief Master Sergeant

The only Allisons in WWII that I have run across that might have been operationally cleared for more than 60"Hg are the F21R/M and F3R/M when using 150 grade fuel, as mentioned in a Bristol document dated Jan'45. They are listed as F/T (full throttle), but I have no idea what full throttle would be for them. The document has the note that full throttle is only allowed if "Allison engines cleared for 150 grade operation provided Thornton induction straightener or American equivalent is fitted" - I have not been able to locate any info on the "Thornton induction straightener".

The same Bristol document mentions that "American Army Order TMI 01-75FF-13 clears the P-38 installation." but does not list the MAP allowed or any additional details..

The same Bristol document mentions that "American Army Order TMI 01-75FF-13 clears the P-38 installation." but does not list the MAP allowed or any additional details..

Mike Williams

Senior Airman

- 572

- Oct 19, 2006

Documents show 65" Hg. MAP was established for 8th AF P-38's while operating with 150 octane fuel.ThomasP

I also have not come across any reports of P-38 engines being operated at greater than 60" of MP, but on page 72 of the P-38 pilot manual, there is a graph that shows 62" of MP at 3000 rpm

Pilots Manual Lockheed P-38 Lightning Pilot Training Manual (3).pdf

The attached chart shows the speed of a P-38L-5 at 64" MP. (note, weight and rpm not given) Now, if these MP's were used operationally or not, I do not know. I have read of pilots on pre P-38J models running their engines above the maximum MP's given in the manuals.

FWIW

Eagledad

Edit: adding this document from spring 44 showing one squadron of P-38s "on actual cross-channel operations" with MAP set at 65". This was a couple of months before all 8th AF fighter units were supplied with 150 grade fuel.

Last edited:

Mike Williams

Senior Airman

- 572

- Oct 19, 2006

These documents show the modifications needed for P-38's to operate at the higher MAPs allowed with 150 grade fuel.The only Allisons in WWII that I have run across that might have been operationally cleared for more than 60"Hg are the F21R/M and F3R/M when using 150 grade fuel, as mentioned in a Bristol document dated Jan'45. They are listed as F/T (full throttle), but I have no idea what full throttle would be for them. The document has the note that full throttle is only allowed if "Allison engines cleared for 150 grade operation provided Thornton induction straightener or American equivalent is fitted" - I have not been able to locate any info on the "Thornton induction straightener".

The same Bristol document mentions that "American Army Order TMI 01-75FF-13 clears the P-38 installation." but does not list the MAP allowed or any additional details..

http://www.wwiiaircraftperformance.org/150grade/ppf-20june44.pdf

Last edited:

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)

Similar threads

- Replies

- 7

- Views

- 2K