Howard Gibson

Senior Airman

We keep discussing engine performance. I am researching this in WWII aircraft and I ought to share stuff.

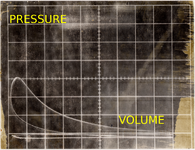

I won't go into the math, but the work done by a cylinder doing a single stroke is the volume swept by the piston, multiplied by the presumably constant pressure. Power is among other things, the rate at which you do work. In the case of a piston, power is the amount of work you do per unit time. The pressure in a spark ignition engine cylinder, not surprisingly, is not constant. When you test an engine, you ought to curious about mean effective pressure. "Mean" is the mathematician's word for "average". Mean effective pressure is average pressure, not pressure that hates children and puppies.

Brake mean effective pressure is pressure calculated from brake horsepower. If you think about it, it is a weird concept. If you mount an engine on a dynamometer with a brake, you can measure torque and speed, and work out power in horsepower or Watts, and brake mean effective pressure (BMEP). Indicated mean effective pressure (IMEP) is measured with the pressure gauge you don't have.

Most of the following data is sucked down off of Wikipedia. Note the cell calculating BMEP. I have a sheet in this spreadsheet that provides unit conversions, mostly to SI.

BMEP gives you a good idea of what is happening inside the engine cylinder. BMEP should give you a good idea of what octane fuel they were using, plus the presence of water and/or methanol injection.

Feel free to speculate wildly about all this.

I won't go into the math, but the work done by a cylinder doing a single stroke is the volume swept by the piston, multiplied by the presumably constant pressure. Power is among other things, the rate at which you do work. In the case of a piston, power is the amount of work you do per unit time. The pressure in a spark ignition engine cylinder, not surprisingly, is not constant. When you test an engine, you ought to curious about mean effective pressure. "Mean" is the mathematician's word for "average". Mean effective pressure is average pressure, not pressure that hates children and puppies.

Brake mean effective pressure is pressure calculated from brake horsepower. If you think about it, it is a weird concept. If you mount an engine on a dynamometer with a brake, you can measure torque and speed, and work out power in horsepower or Watts, and brake mean effective pressure (BMEP). Indicated mean effective pressure (IMEP) is measured with the pressure gauge you don't have.

Most of the following data is sucked down off of Wikipedia. Note the cell calculating BMEP. I have a sheet in this spreadsheet that provides unit conversions, mostly to SI.

BMEP gives you a good idea of what is happening inside the engine cylinder. BMEP should give you a good idea of what octane fuel they were using, plus the presence of water and/or methanol injection.

Feel free to speculate wildly about all this.