rrmerlin60

Airman

- 22

- Dec 18, 2009

Hello All;

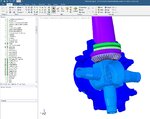

I just joined, but have been watching this forum for a while. I am almost done creating the CAD models for a Mustang 24D50 propeller. Most parts are quite a challenge, but I feel that I'm doing OK. The blades are really hard to loft smoothly.

The purpose of doing the CAD model, is so that I can 3D print the propeller, and the complete hub, although the 4 blades will be clipped. The propeller, once assembled, will be mounted onto my Packard Merlin -9 engine. It's not a complete engine, and has many 3D printed parts as well. It will never actually run.

I would like to have any good photos I can of the propeller hub parts or blades. They are surprisingly scarce on the web. Again, it's specifically the 24D50 propeller, with paddle blades (not cuffed). Anyone have decent pics of internal parts ?

If anyone has an interest in seeing what I'm doing, please visit my Flickr page. By the way, I am not selling anything, in case you're curious. I just do this as a guilty pleasure. If you look under "Tom's Merlin Parts" all the white items are printed Nylon parts, full size. It's taken me years to get to this point. The other metal parts are real.

Here is the link; rrmerlin60's albums | Flickr

Thanks for any photos you might have. Cheers, Tom.

I just joined, but have been watching this forum for a while. I am almost done creating the CAD models for a Mustang 24D50 propeller. Most parts are quite a challenge, but I feel that I'm doing OK. The blades are really hard to loft smoothly.

The purpose of doing the CAD model, is so that I can 3D print the propeller, and the complete hub, although the 4 blades will be clipped. The propeller, once assembled, will be mounted onto my Packard Merlin -9 engine. It's not a complete engine, and has many 3D printed parts as well. It will never actually run.

I would like to have any good photos I can of the propeller hub parts or blades. They are surprisingly scarce on the web. Again, it's specifically the 24D50 propeller, with paddle blades (not cuffed). Anyone have decent pics of internal parts ?

If anyone has an interest in seeing what I'm doing, please visit my Flickr page. By the way, I am not selling anything, in case you're curious. I just do this as a guilty pleasure. If you look under "Tom's Merlin Parts" all the white items are printed Nylon parts, full size. It's taken me years to get to this point. The other metal parts are real.

Here is the link; rrmerlin60's albums | Flickr

Thanks for any photos you might have. Cheers, Tom.