Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Balandin Engine.

- Thread starter jerryw

- Start date

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

More options

Who Replied?Google is your friend!

View: https://www.youtube.com/watch?v=PSGbf0AWXlA

View: https://www.youtube.com/watch?v=9QEjmK0JYb0

As you see it's not really without con rods but it is a bit different to the norm.

regards

JG

View: https://www.youtube.com/watch?v=PSGbf0AWXlA

View: https://www.youtube.com/watch?v=9QEjmK0JYb0

As you see it's not really without con rods but it is a bit different to the norm.

regards

JG

- Thread starter

- #3

jerryw

Airman 1st Class

I've had a look at these "You Tube" references.

They are not much help at all.

They are not much help at all.

From the few references easily found, it would seem that this engine is similar to all typical internal combustion engines with the exception of the crankshaft arrangement. Instead of using conventional crankpins with conrods, Balandin devised a means of using eccentric components (as were commonly found on steam engine valve gear, oil and water pumps for example) to make the connection between the reciprocal and rotational motions. While this may have simplified the piston end, it would also have made the crank assembly far more complex in order to negate the movement perpendicular to (side to side of) the piston stroke. The Utube animations indicate this problem without commenting upon it.

Unfortunately, the resolution of the drawings in your original post makes it impossible to explore much of the detail. I suspect even that perhaps the drawings have been doctored with the intention of not showing how it works.

Hope that helps.

If not, perhaps try and explain which part(s) are not clear to you.

JG

Unfortunately, the resolution of the drawings in your original post makes it impossible to explore much of the detail. I suspect even that perhaps the drawings have been doctored with the intention of not showing how it works.

Hope that helps.

If not, perhaps try and explain which part(s) are not clear to you.

JG

- Thread starter

- #5

jerryw

Airman 1st Class

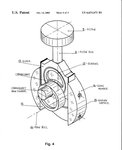

Below is a drawing from a US patent which describes a Balandin-type engine. The improvement applied for is just in the way the slider-guides are located in the main body.

Even in this, it is very difficult to see how the reciprocal movement is translated into rotary kind.

Patent says, "The piston rods, being in the pivoted joint with the crankshaft put it in planetary motion during which the crankshaft rotates around its axis and around the main axis(16)."

Very hard to follow!!

Even in this, it is very difficult to see how the reciprocal movement is translated into rotary kind.

Patent says, "The piston rods, being in the pivoted joint with the crankshaft put it in planetary motion during which the crankshaft rotates around its axis and around the main axis(16)."

Very hard to follow!!

Attachments

- Thread starter

- #7

jerryw

Airman 1st Class

John,

Finally got round to printing out your drawing and having a good look at it!

Many thanks for your time and effort.

The drawing from US Patent No. 6,631,671 is from an engine designed to be a 90 deg. V-twin so presumably, the part labelled, "crankshaft main journal" is embedded in a slider operating at right angles to the one shown.

Question is, are "crankshaft" and "cr. main journ." joined or linked? All the description in the patent doc. only ever refers to "a crankshaft" or "the crankshaft", singular.

The U-tube simulations almost show the situation but not quite!

Cheers, Jerry.

Finally got round to printing out your drawing and having a good look at it!

Many thanks for your time and effort.

The drawing from US Patent No. 6,631,671 is from an engine designed to be a 90 deg. V-twin so presumably, the part labelled, "crankshaft main journal" is embedded in a slider operating at right angles to the one shown.

Question is, are "crankshaft" and "cr. main journ." joined or linked? All the description in the patent doc. only ever refers to "a crankshaft" or "the crankshaft", singular.

The U-tube simulations almost show the situation but not quite!

Cheers, Jerry.

Jerry.

Here's a better explanation of this engine. Still a dog in my humble opinion but not quite the absolute mongrel I thought it was earlier.

The eccentric component does not rotate fully as I earlier suggested but actually oscillates about the centre position. This must be somewhat less than 180 degrees in total to prevent things going awry and this then dictates that the radius of the main crankshaft must be less than the radius of the offset of the eccentric part.

I have drawn the series of moves over one crankshaft revolution and hopefully you will work out for yourself what is happening.

Below this is a drawing in which I have removed the eccentric part and placed a typical connecting rod between the piston rod and crankshaft journal while maintaining the original sliding parts. This should indicate how the effect of this system is actually more or less the same as that of a crosshead engine which were very common on steam engines and also on many large marine diesels.

The scale of the patent drawing is not accurate which helps confuse. Also the part labelled 'crankshaft main journal' appears to be part of the eccentric mechanisms although this would be part of the crankshaft with the eccentric parts rotating on it.

A further confusion is that if the engine in the patent drawing was really to be a 90 degree Vee twin, the front eccentric part would have to be in a different location altogether.

In the drawing the piston shown is at TDC. If the engine was to run on a two stroke cycle then at this moment, the second piston would have to be at BDC. The centre axis of how ever many pistons are fitted must pass through the crankshaft main axis and hence the second piston would therefore have to be immediately beside the existing piston. Impossible! Alternately, if the engine were running as a four stroke, the pistons would need to be at TDC simultaneously and therefore the second piston would have to be fitted directly below the parts drawn which would be possible.

In order to be a 90 degree twin there would have to be a second 'crankshaft main journal' at 90 degrees offset from the one shown (which appears to be the arrangement in the first drawing you posted).

Whether this second journal is to the right or left depends on which side the new cylinder will be added to the drawing and whether the engine is going to run as a 2 or 4 stroke (to determine if the second piston needs to be at TDC or BDC).

Hope that makes it all much clearer although I have my doubts that it really will.

JG

Here's a better explanation of this engine. Still a dog in my humble opinion but not quite the absolute mongrel I thought it was earlier.

The eccentric component does not rotate fully as I earlier suggested but actually oscillates about the centre position. This must be somewhat less than 180 degrees in total to prevent things going awry and this then dictates that the radius of the main crankshaft must be less than the radius of the offset of the eccentric part.

I have drawn the series of moves over one crankshaft revolution and hopefully you will work out for yourself what is happening.

Below this is a drawing in which I have removed the eccentric part and placed a typical connecting rod between the piston rod and crankshaft journal while maintaining the original sliding parts. This should indicate how the effect of this system is actually more or less the same as that of a crosshead engine which were very common on steam engines and also on many large marine diesels.

The scale of the patent drawing is not accurate which helps confuse. Also the part labelled 'crankshaft main journal' appears to be part of the eccentric mechanisms although this would be part of the crankshaft with the eccentric parts rotating on it.

A further confusion is that if the engine in the patent drawing was really to be a 90 degree Vee twin, the front eccentric part would have to be in a different location altogether.

In the drawing the piston shown is at TDC. If the engine was to run on a two stroke cycle then at this moment, the second piston would have to be at BDC. The centre axis of how ever many pistons are fitted must pass through the crankshaft main axis and hence the second piston would therefore have to be immediately beside the existing piston. Impossible! Alternately, if the engine were running as a four stroke, the pistons would need to be at TDC simultaneously and therefore the second piston would have to be fitted directly below the parts drawn which would be possible.

In order to be a 90 degree twin there would have to be a second 'crankshaft main journal' at 90 degrees offset from the one shown (which appears to be the arrangement in the first drawing you posted).

Whether this second journal is to the right or left depends on which side the new cylinder will be added to the drawing and whether the engine is going to run as a 2 or 4 stroke (to determine if the second piston needs to be at TDC or BDC).

Hope that makes it all much clearer although I have my doubts that it really will.

JG

Attachments

- Thread starter

- #9

jerryw

Airman 1st Class

John,

Thanks for your reply and particularly for another magnificent drawing to attempt an explanation as to how the Balandin Engine works.

Your suggestion that there are TWO oscillating components in this engine I find hard to accept. In the US Patent engine, the part inside the slider is connected directly to the propeller so if it oscillated, so would the prop!!

I think we have a bit further to go.

Thanks for your reply and particularly for another magnificent drawing to attempt an explanation as to how the Balandin Engine works.

Your suggestion that there are TWO oscillating components in this engine I find hard to accept. In the US Patent engine, the part inside the slider is connected directly to the propeller so if it oscillated, so would the prop!!

I think we have a bit further to go.

Balandin make use of background material -- for example, Parsons Epicyclic Engine ( The Parsons Epicyclic Engine. ), provided that, use original design in detal and technical decision.

"The best" Balandin's model -- М-127К: direct injections fuel, double-acting, turbo compound X-architecture 24-cylinder four-stroke liquid cooling engine, power -- 10.000 hp@2600rpm.

All specifics detals discussed in monography "Бесшатунные двигатели внутреннего сгорания" (Conrod-free internal combustion engine), decent drawings and diagrams, example experimental engine, hystory... Download here: zSHARE - balandin.djvu, in the Russian language. The primary source of information!

internal combustion engine), decent drawings and diagrams, example experimental engine, hystory... Download here: zSHARE - balandin.djvu, in the Russian language. The primary source of information!

Fundamental problem all engine design of Balandin -- save preservation engineering kinematics. This meet the test of experiment, Balandin's engines is very popular alternative design, DIY, of course.

P.S.Excuse my english

"The best" Balandin's model -- М-127К: direct injections fuel, double-acting, turbo compound X-architecture 24-cylinder four-stroke liquid cooling engine, power -- 10.000 hp@2600rpm.

All specifics detals discussed in monography "Бесшатунные двигатели внутреннего сгорания" (Conrod-free

Fundamental problem all engine design of Balandin -- save preservation engineering kinematics. This meet the test of experiment, Balandin's engines is very popular alternative design, DIY, of course.

P.S.Excuse my english

Deskpilot

Airman

I'm looking for info on the Palandin-Parsons 2 stroke 'radial' engine as seen on youtube. Unfortunately the info above doesn't cover this particular engine. The cut away drawing shown is a 4 stroker. I'm not going to get into what JG was on about re oscillating components but the model on youtube is quite straight forward in that the crankshaft rotates as per normal. What I really want to know is, how is the mixtures compressed in the central compartment. Are there walls twix the piston pairs? Is there some method of subdividing that same area twix top and bottom pistons so that compression can take place beneath each piston? Remember, it a 2 stroke. With only 3 moving parts, this has to be one of the simplest engines around, at least, on the face of it.

All and any comments appreciated and answered.

BTW, I do realise that this is an old thread.

All and any comments appreciated and answered.

BTW, I do realise that this is an old thread.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)