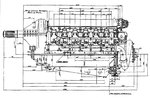

Anyone have any data, images or links they can share regarding the Klimov VK-107 engine. Cross section drawings would be great.

What little i have read about this engine is conflicting or how shall we say... confused.

I have only seen one image, and that is a front quarter view that does not show many important parts of this engine. .

This engine gets briefly discussed on this forum in an earlier thread about M-105 power outputs / ratings.

Best I could make out from the table in that thread, it looks like the often quoted 1650 PS / HP output came required running at 3200 rpm.

That high of an rpm seems quite daring, at least based on what I think I know about lack of quality if not outright shoddy construction during that era in the Soviet Union.

What little i have read about this engine is conflicting or how shall we say... confused.

I have only seen one image, and that is a front quarter view that does not show many important parts of this engine. .

This engine gets briefly discussed on this forum in an earlier thread about M-105 power outputs / ratings.

Best I could make out from the table in that thread, it looks like the often quoted 1650 PS / HP output came required running at 3200 rpm.

That high of an rpm seems quite daring, at least based on what I think I know about lack of quality if not outright shoddy construction during that era in the Soviet Union.

Last edited: