MiTasol

Captain

DeHavilland used magnesium in the Gipsy Major series of engines, and I understand in the Gipsy Queen and six series as well. The top cover and rear case was Mg.

The Gypsy Major engine I have has an Al alloy crankcase but agree that they used Mg in many of the secondary castings. Same with the six and Queen. Although the top cover is attached to the crankcase it is not primary structure and, as I read his comment, the OP was discussing primary structure rather than covers and secondary structure.

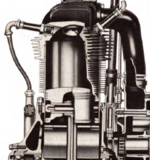

I'm curious which engine type can take the most damage and make it home my guess would be to say the V and H pattens wouldn't make it if they took any damage if a merlin or db601 takes a .30 in or .50 into the block i wouldn't say it would make it home.

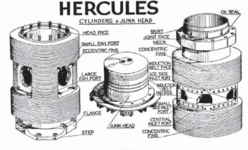

What he is calling the block is the crankcase and, in the case of an inline, cylinder banks. Being a newbie he is not aware how inlines like the Allison and Merlin were built. He is thinking that the crankcase and cylinder blocks are a single unit with removable heads like on a vehicle instead of separate components with the head integral with the cylinders like on an aircraft. Give him time and he will learn.

Last edited: