Was there anything like a sludge trap built in? They have such thigs on pipelines and refineries.Gateway Aviation in Canada in the late 60s and early 70's when I worked for them had a strict policy of doubling oil changes (so every 25 hours instead of 50 on the Pratt's) and part of their oil change procedure was and oil dilution and to fill the oil tank with fuel and leave sit while doing other work (even if that was only cleaning the aircraft). When the tank was drained the first gallon or so was thick sludge. Same with the oil cooler.

We bought a "new" Otter with some 200 hours on its engine and on its post delivery oil change I had to change oil half a dozen times before the oil filter was clean enough for me to consider letting it fly. Most of those oil changes the oil cooler drain ran like tar. After five hours we did another oil change and the filter was loaded with carbon deposits and oil cooler still did not drain as clean as other aircraft in the fleet that were coming close to overhaul.

Just because there is no dust around does not stop the inside of the engines and oil system filling with combustion byproducts, varnish and other undesirable shit.

At the time Gateway were approved to run their 985, 1340 and 1830 radial engines 50% longer between overhauls than other operators and they had a lower overhaul cost than other operators because there was little or no baked on sludge inside the engine.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Service, Overhaul intervals for WW2 aircraft engines question.

- Thread starter bdefen

- Start date

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

More options

Who Replied?I thought I covered that in the bit you didnt highlight. From start to finish the Merlin had a lot of fundamental things changed from the ramp head, carburettors, updraft to downdraft, superchargers and all work on ancilliaries.'As did all the other engines. Like the Merlin the Wright R-1820 more than doubled in horsepower during it's life. The oldest I worked on was just under 700 horsepower and un-geared. The latest I worked on was in the Grumman tracker and produced 1500+hp. If my memory is correct there were some less powerful versions as well.

With most/all manufacturers some models produced no more power than their predecessors but had considerably better operating reliability.

MiTasol

Captain

No aircraft engine that I have worked on has a sludge trap.Was there anything like a sludge trap built in? They have such thigs on pipelines and refineries.

Surprising to me, you can isolate the trap and drain it every time the plane lands.No aircraft engine that I have worked on has a sludge trap.

ThomasP

Chief Master Sergeant

Hey pbehn,

I can not guarantee this is 100% true, but as far as I am aware the sludge trap is not used on ICE engines that use replaceable or cleanable oil filters. Also as far as I am aware, pretty much all the turbine engines use oil filters as well as oil scavenge filters, and so (probably?) would not benefit from sludge traps.

Out of curiosity, do the refineries and associated piping systems use any replaceable (or possibly cleanable) filter units in the areas you were referring to?

I can not guarantee this is 100% true, but as far as I am aware the sludge trap is not used on ICE engines that use replaceable or cleanable oil filters. Also as far as I am aware, pretty much all the turbine engines use oil filters as well as oil scavenge filters, and so (probably?) would not benefit from sludge traps.

Out of curiosity, do the refineries and associated piping systems use any replaceable (or possibly cleanable) filter units in the areas you were referring to?

MiTasol

Captain

It has probably been classified as not necessary on turbines as they mainly run a synthetic oil so filtering is all it needs and an unacceptable weight and maintenance penalty on light aircraft. On bug smashers depending on pilots to drain it after every flight is fraught with danger as is the possibility that they do not fully close the drain which has the potential to cause an in flight shut down.

It may well be technology that was developed post war when the large engines were already doomed to extinction for the vast majority of operators.

It may well be technology that was developed post war when the large engines were already doomed to extinction for the vast majority of operators.

Simon Thomas

Senior Airman

The Bristol Hercules VI XI XVI XVII XVIII operators handbook (August, 1945) indicates that they are fitted with centrifugers for the engine oil.

I checked to see how often the engine oil is replaced, and surprisingly the routine maintenance section does not specify any engine oil changes between overhauls.

The oil filter is to be cleaned at each minor inspection.

The accessory gearbox requires oil changes at alternate minor inspections, which is also when the centrifugers are required to be removed and cleaned.

I checked to see how often the engine oil is replaced, and surprisingly the routine maintenance section does not specify any engine oil changes between overhauls.

The oil filter is to be cleaned at each minor inspection.

The accessory gearbox requires oil changes at alternate minor inspections, which is also when the centrifugers are required to be removed and cleaned.

FLYBOYJ

"THE GREAT GAZOO"

Does the operator's handbook indicate the intervals for a "minor inspection"?The Bristol Hercules VI XI XVI XVII XVIII operators handbook (August, 1945) indicates that they are fitted with centrifugers for the engine oil.

I checked to see how often the engine oil is replaced, and surprisingly the routine maintenance section does not specify any engine oil changes between overhauls.

The oil filter is to be cleaned at each minor inspection.

The accessory gearbox requires oil changes at alternate minor inspections, which is also when the centrifugers are required to be removed and cleaned.

Normally detailed maintenance information will not be found in the operator's handbook, you'll have to go to the actual engine maintenance manual.

MiTasol

Captain

Simon - the later engines I worked on used in the Bristol Freighters did did not have that feature from memory so it was probably deleted in later engines. I distinctly remember a purolator type filter low down on the blower case which was a pig to remove and two other filters, one in the sump and one in the tank. Oil changes were regular (cant remember hours) and the oil tank was flushed before filling but that may have been an operator requirement.

Flyboy - I am fairly sure I scanned and posted the Hercules 630(?) series Engine Maintenance Manual to the forum so have a look for that. If not let me know and I will post it. I cannot remember if it contains maintenance schedules. We worked from the the schedules in the Airframe manual.

Flyboy - I am fairly sure I scanned and posted the Hercules 630(?) series Engine Maintenance Manual to the forum so have a look for that. If not let me know and I will post it. I cannot remember if it contains maintenance schedules. We worked from the the schedules in the Airframe manual.

Crimea_River

Marshal

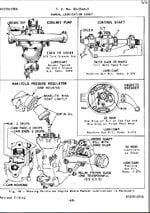

Excerpts from T.O. 02-55A A-2 Handbook of Service Instructions for Packard Merlin 28, 29, 31:

Attachments

FLYBOYJ

"THE GREAT GAZOO"

I just did a search for it in our technical section and can't find anything, although a few people were looking for Hercules manualsFlyboy - I am fairly sure I scanned and posted the Hercules 630(?) series Engine Maintenance Manual to the forum so have a look for that. If not let me know and I will post it. I cannot remember if it contains maintenance schedules. We worked from the the schedules in the Airframe manual.

Simon Thomas

Senior Airman

That manual is in here: Bristol Engines.......... used on the Beaufighter

FLYBOYJ

"THE GREAT GAZOO"

You have better eyes than me! LOL!That manual is in here: Bristol Engines.......... used on the Beaufighter

Looks like the manual calls out 100 hour engine oil changes, Pare 3, chapter 2, page 4

Simon Thomas

Senior Airman

The Hercules VI XI XVI XVII XVIII handbook does not correlate hours to inspection type.

It appears that the Hercules VI XI XVI XVII XVIII has the centrifuger and no oil drain period. The centrifuger is cleaned at alternate minor inspections.

The Hercules 130 and 131 has no centrifuger, it does have the purolator and it has a 200 hour oil drain period. The purolator is cleaned on a 100 hour schedule.

The Hercules 630 has no centrifuger, it does have the purolator and it has a 100 hour oil drain period. The purolator filter is normally only removed during the overhaul of the engine.

Seems Bristol were trying something different with every model Hercules.

The Wright GR2600-A5B has an oil drain period of 50 hours.

The Merlin II is 40 hours.

It appears that the Hercules VI XI XVI XVII XVIII has the centrifuger and no oil drain period. The centrifuger is cleaned at alternate minor inspections.

The Hercules 130 and 131 has no centrifuger, it does have the purolator and it has a 200 hour oil drain period. The purolator is cleaned on a 100 hour schedule.

The Hercules 630 has no centrifuger, it does have the purolator and it has a 100 hour oil drain period. The purolator filter is normally only removed during the overhaul of the engine.

Seems Bristol were trying something different with every model Hercules.

The Wright GR2600-A5B has an oil drain period of 50 hours.

The Merlin II is 40 hours.

- Thread starter

- #36

bdefen

Senior Airman

I'll bet "normal maintenance" on a bird so rare and expensive (i.e. cost to recover, restore, and operate Dottie Mae) is very frequent and detailed. IMHO, probably well in excess of the manufacturer's/military regimen.I wonder what he considered "normal maintenance?"

MiTasol makes great points on his post #13)

With that said I would wonder what the manufacturer's original guidelines were for oil changes on a P-47D, I'd guess the traditional 50 hour increment. The reason why I ask is because to gain an airworthiness certificate for that aircraft, the owner/operator would have to present a maintenance program to the FAA and if the owner/ operator wanted to deviate from what the manufacturer specified in the original maintenance manuals, they would have to put up a very rational and convincing argument. I know on many turbine engines running synthetics, there are no oil change intervals, you just add oil as the engine consumes it providing it is not at an excessive level specified in the maintenance manual.

FLYBOYJ

"THE GREAT GAZOO"

I've helped maintain a few, and usually most owners go beyond what's in the maintenance manuals and writes that into their FAA approved maintenance programI'll bet "normal maintenance" on a bird so rare and expensive (i.e. cost to recover, restore, and operate Dottie Mae) is very frequent and detailed. IMHO, probably well in excess of the manufacturer's/military regimen.

To put some fact to fiction and stories I am attaching T.O. 00-25-4, Aircraft Maintenance Procedure and Overhaul of Engines. It specifies the approved TBO for each engine being used within the Army Air Forces in 1942 and 1943. It also identifies the requirements before exceeding the established TBO hours.

Attachments

MiTasol

Captain

I often wondered why the R-975 was not a popular engine post war and that chart suggests why - 375hr TBO on some models, 500 on others versus the R-985s at 700 hours on all models

YakMan

Airman

1) I would say there would be too many differences between these engines to give a meaningful answer. You have air cooled radials and liquid cooled in-line engines listed here - wildly different in operation. Suffice to say, each aeroplane fitted with a certain engine would have a fixed schedule of maintenance (if it survived that long - most did not!).If not damaged in combat or other use, what were the typical hours operation of P&W, Bristol, and BMW radial engines, as well as D-B 600 series, Jumo 200 series, Allison, and R-R Merlin engines before certain maintenance was required?

Fuel (presumably), oil, coolant, hydraulic fluids checked and added for each sortie?

How many hours before "tune ups" like carburetor or FI adjustments, timing, ignition, valve adjustments, spark plugs, etc?

And how many hours before major overhauls, like valves, valve seats, rings, pistons, bearings, re-boring, etc.?

At what point was an engine considered worn out and not rebuildable, and therefore scrapped?

Was the "power egg" system used by most air forces?

2) Again, every aeroplane would have its own list of items that needed to be completed in a turn around, some lists were no doubt added to, or reduced, based on experience in the field.

3) Tune ups were not carried out as far as I know, you had routine maintenance at the fixed interval but everything else was not interfered with unless disturbed in the course of other work. For example the valve clearances and magneto timing on the P&W Wasp Junior (R985) are not altered between overhaul (unless necessary).

4) Each engine had its own TBO or Time Between Overhauls. In the case of Russian engines these were only noted in the first engine log and set by the factory dependant on the aircraft to which the engine was being fitted so the same ASh-82FN engine might easily have different TBOs depending on its fitment.

5) If the pilot or flight engineer noted a large lack of performance and there was no control or accessory issue, the engine would be changed, same if it used unusually large amounts of oil and there were no obvious leaks, there were not too many other ways of telling!

6) I would say not, the power egg was not a universal 'thing' I don't think, most aircraft engines are a big job to change as a lot is 'built around it' - its a great idea, four bolts, two control connections and a few hoses sounds wonderful - I wish the aircraft I look after had that!

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)