- Thread starter

- #21

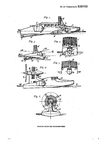

Steam condenser air exhaust creates approximately 2,000 lbs of additional per engine at takeoff.

At 30,000 ft and 400mph air temperature after condenser is 261F and jet nozzle pressure ratio is 1.5. Aircraft speed is 587 ftps, jet exhaust velocity is 932 ftps. Air flow 370lbs/s per engine. Each steam turbine produces 6,213HP. Net propulsion efficiency based on boiler efficiency 90% is 11.8% which is equivalent of 15% efficiency gasoline engine with propeller. Jet fuel flow is 16,000 lbs per hour, coal/oil mix(65%/35%) flow is 19,200 lbs per hour. These are very high numbers and comparable to an equivalent zero bypass turbojet aircraft fuel consumption at the same speed.

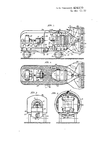

Weight of the complete powerplant based on 1938s Nathan Price's 5000hp turbocharged steam generator(1,800 lbs) and calculations from the technical papers mentioned above is 2x(1,800+6,000)=15,600 lbs or 12.6% of the takeoff weight 56,000 kg(123,457 lbs).

Considering that the steam power plant is 5,000 lbs heavier, the available fuel weight is about 33,000 lbs. It means that this aircraft can fly up to two hours on jet fuel or 1.5 hour on coal/oil mix.

At 30,000 ft and 400mph air temperature after condenser is 261F and jet nozzle pressure ratio is 1.5. Aircraft speed is 587 ftps, jet exhaust velocity is 932 ftps. Air flow 370lbs/s per engine. Each steam turbine produces 6,213HP. Net propulsion efficiency based on boiler efficiency 90% is 11.8% which is equivalent of 15% efficiency gasoline engine with propeller. Jet fuel flow is 16,000 lbs per hour, coal/oil mix(65%/35%) flow is 19,200 lbs per hour. These are very high numbers and comparable to an equivalent zero bypass turbojet aircraft fuel consumption at the same speed.

Weight of the complete powerplant based on 1938s Nathan Price's 5000hp turbocharged steam generator(1,800 lbs) and calculations from the technical papers mentioned above is 2x(1,800+6,000)=15,600 lbs or 12.6% of the takeoff weight 56,000 kg(123,457 lbs).

Considering that the steam power plant is 5,000 lbs heavier, the available fuel weight is about 33,000 lbs. It means that this aircraft can fly up to two hours on jet fuel or 1.5 hour on coal/oil mix.

Last edited: