Grant Barr

Senior Airman

Time to kick off the thread for the next build on my list. After having just completed an old Classic Airframes kit it is refreshing to open the box on a much newer kit from Eduard (although I understand this may be a re-box of the Gavia kit).

(Box art shot courtesy of Scalemates)

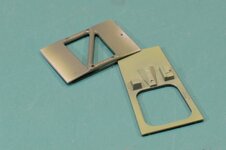

The box contents are quite comprehensive, with 4 main sprue trees in grey styrene and 1 in clear, along with some neat resin parts and two PE sheets. One PE sheet is straight brass, with the other cockpit sheet being the pre-painted fare we've come to expect from Eduard.

Even though it is a limited-edition kit with some extra resin and PE goodies, but I could not resist the temptation to add some more after-market bits to this. SBS make a very nice resin engine, cowl and prop for the Eduard/Gavia kit, and I acquired this not too long after buying the Lysander.

This boxing of the Lysander provides options and decals to support 7 different paint schemes, although three are variations on a theme for Finnish aircraft, two being in standard UK daytime finish and one each for the East Indies and night operations schemes.

I had originally intended to do one of the standard daytime versions, but another kit I have further down the "build list" has prompted me to choose again. I have opted to do the Option B, which is a Finnish Lysander with a white limewashed paint scheme.

To do this paint scheme, the plan is to show the aircraft sometime after the limewash was applied, once the white paint has been subject to wearing back down to the original paint scheme. So to achieve this effect I will need to first paint the standard olive green/black camouflage used by the Finnish AF as shown below.

Once this paint scheme is complete, I can then apply a very thin covering of a whitewash colour to simulate a worn winter camouflage. With luck I won't get too heavy handed with this and end up with an interesting, weathered finish. I really do need to practice this type of affect as I have a pending build that has quite some personal significance and I want to have the skills to get that one right.

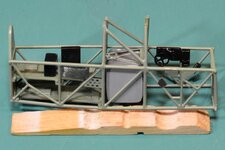

I have made a start on the initial steps to building the cockpit up. There are a lot of small, delicate and very fragile parts for the cockpit, and they all need to be carefully removed from the sprues and cleaned up ready for assembly/paint. I will be taking my time at this point as I have been known to "rush" the early stages of a build, wanting to "get it done"!

I don't have any photos of parts clean up (it's all a bit too boring to document to be honest) but will hopefully have some shots of assembled/painted components in the next post.

(Box art shot courtesy of Scalemates)

The box contents are quite comprehensive, with 4 main sprue trees in grey styrene and 1 in clear, along with some neat resin parts and two PE sheets. One PE sheet is straight brass, with the other cockpit sheet being the pre-painted fare we've come to expect from Eduard.

Even though it is a limited-edition kit with some extra resin and PE goodies, but I could not resist the temptation to add some more after-market bits to this. SBS make a very nice resin engine, cowl and prop for the Eduard/Gavia kit, and I acquired this not too long after buying the Lysander.

This boxing of the Lysander provides options and decals to support 7 different paint schemes, although three are variations on a theme for Finnish aircraft, two being in standard UK daytime finish and one each for the East Indies and night operations schemes.

I had originally intended to do one of the standard daytime versions, but another kit I have further down the "build list" has prompted me to choose again. I have opted to do the Option B, which is a Finnish Lysander with a white limewashed paint scheme.

To do this paint scheme, the plan is to show the aircraft sometime after the limewash was applied, once the white paint has been subject to wearing back down to the original paint scheme. So to achieve this effect I will need to first paint the standard olive green/black camouflage used by the Finnish AF as shown below.

Once this paint scheme is complete, I can then apply a very thin covering of a whitewash colour to simulate a worn winter camouflage. With luck I won't get too heavy handed with this and end up with an interesting, weathered finish. I really do need to practice this type of affect as I have a pending build that has quite some personal significance and I want to have the skills to get that one right.

I have made a start on the initial steps to building the cockpit up. There are a lot of small, delicate and very fragile parts for the cockpit, and they all need to be carefully removed from the sprues and cleaned up ready for assembly/paint. I will be taking my time at this point as I have been known to "rush" the early stages of a build, wanting to "get it done"!

I don't have any photos of parts clean up (it's all a bit too boring to document to be honest) but will hopefully have some shots of assembled/painted components in the next post.