- Thread starter

- #81

It can't be both.Both

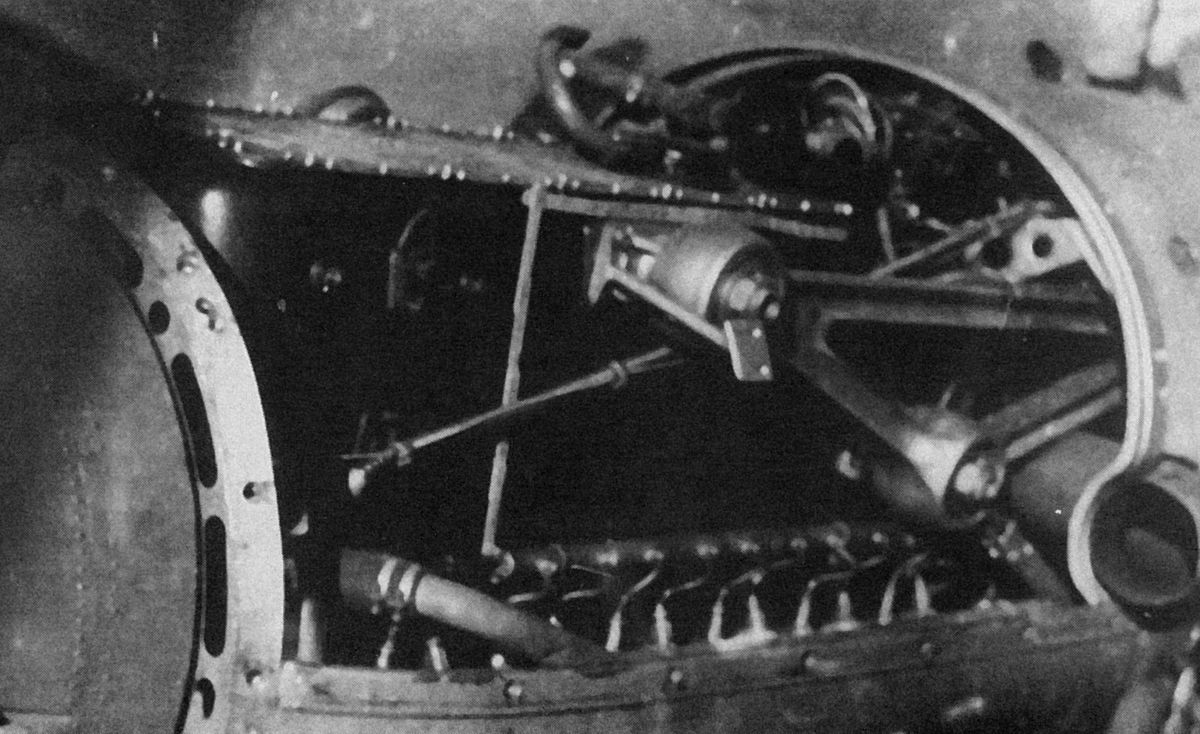

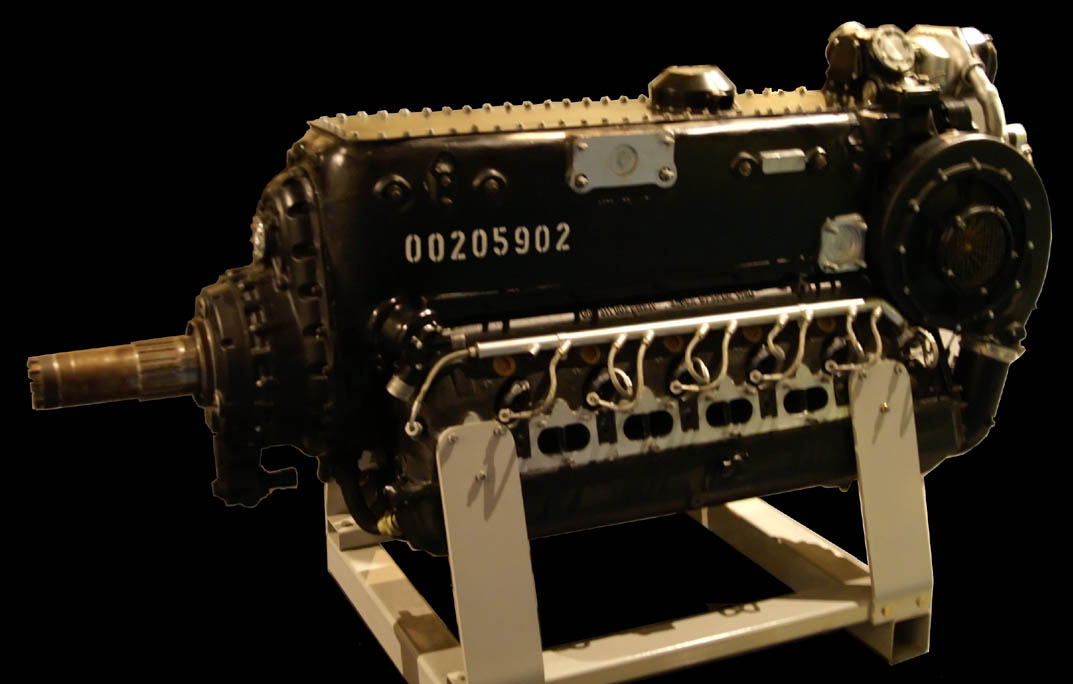

Looking at the surface-evaporative cooling system: It's cooling system takes up nearly the whole aircraft.

In this thread, there is no surface cooling on the He 100.

When he said "high temperature cooling", I assume this didn't mean just temperature, but pressure as well?

We can ask him when he stops by on this forum