And on the P-39 the coolant radiator was put in the leading edges of both wings?Coolant radiator was in left (facing forward) wing leading edge. Did not have an adjustable outlet.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XP-39 Wind Tunnel Tuft Tests

- Thread starter kool kitty89

- Start date

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

More options

Who Replied?Shortround6

Lieutenant General

no.

XP-39 with radiator inlet.

in left wing root.

XP-39 with radiator outlet about midwing

intersects the wing walkway.

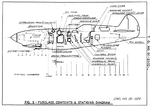

P-39s had an inlet in each wing but the radiator was in the wing center section under the engine. Outlet was at the rear of the wing with an oil cooler flap on each side.

see bottom picture in Post #20 of this thread

XP-39 with radiator inlet.

in left wing root.

XP-39 with radiator outlet about midwing

intersects the wing walkway.

P-39s had an inlet in each wing but the radiator was in the wing center section under the engine. Outlet was at the rear of the wing with an oil cooler flap on each side.

see bottom picture in Post #20 of this thread

Shortround6

Lieutenant General

duplicate

P-39 Expert

Non-Expert

Like I have said before, that turbo installation in the P-39 would have made Rube Goldberg proud. I don't think it would ever have been reliable and Bell/AAF made a wise move in deleting it in order to get the P-39 into series production in time for WWII.

All they really needed to make the early P-39s(D,F,K and L) high altitude planes (in 1942) was less weight.

All they really needed to make the early P-39s(D,F,K and L) high altitude planes (in 1942) was less weight.

No, I get that in the way it was installed below the engine: However, if like on the P-63, the oil tank was moved forward and the turbo was placed behind the engine instead of under it, would such a design have been workable?Like I have said before, that turbo installation in the P-39 would have made Rube Goldberg proud.

Also, would there have been enough room to mount the intercooler as placed?

wuzak

Captain

All they really needed to make the early P-39s(D,F,K and L) high altitude planes (in 1942) was less weight.

And a better high altitude supercharger for the engine.

P-39 Expert

Non-Expert

The oil tank wasn't moved on the P-63, it was the coolant tank that was moved up between the pilot and engine that made room for the mechanical second stage supercharger (not a turbo). There was enough room there for the mechanical second stage but not a turbo which required more space. Plus all the internal ducting (exhaust to turbo to intercooler to carburetor) and the intercooler itself, none of which was used/needed on the P-63. Adding the turbo where the oil tank was would have caused a CG problem also. Workable is the key word, and that would have been difficult without substantially enlarging the P-39/63. The P-47 used this arrangement (turbo in the rear fuselage) and was a much larger plane than the P-39/63. Much easier/quicker to use the mechanical second stage rather than the turbo. Just my opinion.No, I get that in the way it was installed below the engine: However, if like on the P-63, the oil tank was moved forward and the turbo was placed behind the engine instead of under it, would such a design have been workable?

Also, would there have been enough room to mount the intercooler as placed?

P-39 Expert

Non-Expert

Obviously the higher supercharger gear ratio (9.6 vs 8.8) in the P-39M/N/Q provided about 100 extra HP and better performance but the earlier D,F,K and L with the 8.8 engines would have benefited greatly from an easy weight reduction program.And a better high altitude supercharger for the engine.

The P-39C (8.8 gears) had the same engine and aerodynamics as the P-39D/F but was about 10mph faster (379mph vs 369mph) and climbed a whopping 1000fpm faster (3720fpm vs 2720fpm), good performance for 1942. The difference was weight since the P-39C weighed only 7075# and the D/F/K/L weighed about 7650#.

Simply remove the (useless) four .30 caliber light machine guns from the wings, the nose armor plate (100#) and the small armor panels in the cockpit turnover bulkhead around the rear armor glass but leave all the rest of the armor plate/glass protecting the pilot and oil tank. A P-39F being produced around the time of Pearl Harbor weighed 5409# empty, add pilot 200#, fuel 720# (std 120gal load), oil 71#, guns/ammo 580# (37mm plus 2x.50calMG and gunsight) and remaining armor plate/glass 129# and this plane weighs 7109#. Not quite 7075# but close enough for government work. That would have been a hot ship in 1942.

Sorry about that...P-39 Expert said:The oil tank wasn't moved on the P-63, it was the coolant tank that was moved up between the pilot and engine that made room for the mechanical second stage supercharger (not a turbo).

The P-63 was originally planned around having an intercooler (not sure where), but ultimately they went with anti-detonant...There was enough room there for the mechanical second stage but not a turbo which required more space. Plus all the internal ducting (exhaust to turbo to intercooler to carburetor) and the intercooler itself, none of which was used/needed on the P-63.

So the turbocharger weighed more than the supercharger, as well as all it's ducting and the intercooler?Adding the turbo where the oil tank was would have caused a CG problem also.

Would lengthening the P-39 to the P-63's length have provided any fix? If not, would an arrangement similar to the YP-37 and YB-38 work (also below the engine but better flow)Workable is the key word, and that would have been difficult without substantially enlarging the P-39/63.

I agree, it's just kind of an intellectual exercise -- see what would/would not work. That, and I don't think Allison had a 2nd stage developed at the time (that said, it could be bolted on without difficulty due to the design).Much easier/quicker to use the mechanical second stage rather than the turbo.

The removal of the 4 x 7.62's seems like a good idea to be honest, I never really understood why they put them in the design: I figure that 2 x 0.50 in the wing, 2 x 0.50 in the nose, and 1 x 37mm would be quite good. As for the nose armor plate, and small panels around the rear-armor glass, do you mean the bulletproof glass or firewall & that metal thing protecting the pilot's head?Simply remove the (useless) four .30 caliber light machine guns from the wings, the nose armor plate (100#) and the small armor panels in the cockpit turnover bulkhead around the rear armor glass but leave all the rest of the armor plate/glass protecting the pilot and oil tank.

P-39 Expert

Non-Expert

The turbo and the mechanical second stage (MSS) probably weighed about the same but if the turbo went where the oil tank was it would be further aft of the CG than the MSS causing (more) balance issues. The ducting issue was mainly internal space not weight.Sorry about that...

The P-63 was originally planned around having an intercooler (not sure where), but ultimately they went with anti-detonant...

So the turbocharger weighed more than the supercharger, as well as all it's ducting and the intercooler?

Would lengthening the P-39 to the P-63's length have provided any fix? If not, would an arrangement similar to the YP-37 and YB-38 work (also below the engine but better flow)

I agree, it's just kind of an intellectual exercise -- see what would/would not work. That, and I don't think Allison had a 2nd stage developed at the time (that said, it could be bolted on without difficulty due to the design).

The removal of the 4 x 7.62's seems like a good idea to be honest, I never really understood why they put them in the design: I figure that 2 x 0.50 in the wing, 2 x 0.50 in the nose, and 1 x 37mm would be quite good. As for the nose armor plate, and small panels around the rear-armor glass, do you mean the bulletproof glass or firewall & that metal thing protecting the pilot's head?

The P-63 was lengthened but it was all in the tail cone, not in the engine compartment. Engine compartment was the same size on both P-39 and P-63. Lengthening was for stability, not internal space for the MSS.

Allison MSS was in production in March 1943, just for time reference.

Those 4x.30cal wing guns ruined the P-39. Without them the plane was lighter and the space vacated by the guns could have been used for more fuel if desired. Main problem was they weren't powerful enough to be effective as the British proved in the Battle of Britain. No other AAF production fighter used them. We can blame our friends the British for the .30 caliber wing guns, they specified them on the export P-400.

Regarding the armor plate, keep the rear armor glass and delete the small pieces of armor on the turnover bulkhead (that metal thing protecting the pilot's head).

P-39 was just too small for a turbo, intercooler and all the internal ducting IMO. Fun to talk about though.

wuzak

Captain

The P-63 was originally planned around having an intercooler (not sure where), but ultimately they went with anti-detonant...

It was a liquid to air intercooler, very much like the one on the Merlin, positioned above the engine stage supercharger. This require relocating the carburetor to the intake of the auxiliary supercharger.

The radiator for the intercooler was, presumably, located with or near the engine radiator.

wuzak

Captain

Those 4x.30cal wing guns ruined the P-39. Without them the plane was lighter and the space vacated by the guns could have been used for more fuel if desired. Main problem was they weren't powerful enough to be effective as the British proved in the Battle of Britain. No other AAF production fighter used them. We can blame our friends the British for the .30 caliber wing guns, they specified them on the export P-400.

The 0.30" mg was a common fitment to American aircraft at the time. The P-40B, in production in 1941, had 2 x 0.50"mgs and 4 x 0.30" mgs.

The early P-39s carried 2 x 0.30" mgs as well as 2 x 0.50" mgs and 1 x 37mm boat anchor. Well before the British ordered the Airacobra I.

If the British specified the extra wing guns it was probably because they felt it was under-armed. Not sure if the 0.50" mgs could have fitted in the P-39's wings, but if they couldn't it would explain why the 2 x 0.30" mgs in each wing were chosen.

Oh, and the BoB was won using, almost exclusively, 0.303" mgs.

OkayThe turbo and the mechanical second stage (MSS) probably weighed about the same but if the turbo went where the oil tank was it would be further aft of the CG than the MSS causing (more) balance issues. The ducting issue was mainly internal space not weight.

Stability usually implies a relationship in control surface effectiveness as well as mass...The P-63 was lengthened but it was all in the tail cone, not in the engine compartment. . . . Lengthening was for stability, not internal space for the MSS.

Those 4x.30cal wing guns ruined the P-39. Without them the plane was lighter and the space vacated by the guns could have been used for more fuel if desired.

- How much weight could be trimmed off by removing the 4 x 0.30" and all their ammo?

- How much fuel could be put in that volume

- Would 2 x 0.50 with normal rpg levels add any significant weight?

It is, isn't it?P-39 was just too small for a turbo, intercooler and all the internal ducting IMO. Fun to talk about though.

I'm not sure how this would have worked, but I know this configuration was pretty similar and worked on the XB-38...

... the problem with the P-37 was the configuration of the radiators producing an excessively long nose.

And the reason for this delay had to do with the fact thatAllison MSS was in production in March 1943, just for time reference.

- There was little demand for inline engines in the United States

- The airlines had little interest as air-cooled engines were more reliable; the NACA cowl greatly improved cooling, and reduced drag

- Raceplane designers seemed to vary: The land-based guys used radials almost exclusively because the engines were lighter for the same power, and used very well designed cowlings, and built their planes as light as possible; the seaplane designers usually used liquid cooled or even surface-evaporative cooling and used the struts and braces as radiator surfaces.

- The USN had little interest in inline engines after the late 1920's or early 1930's: Radials were more compact and more reliable, though they were willing, at times, to evaluate inlines if they provided a marked improvement in performance, and as a result funded the Lycoming H-2470, Pratt & Whitney X-1800/H-2240/2600, H-3130/3730

- The USAAC really was the only organization that wanted inline engines, and to this effect, they funded the Continental O-1230/I-1430 Hyper-engine, the V-1710, X-3420/V-3420, and the Lycoming O-1230

- The massive funding of a large number of inline-engines: Including the Continental O-1230/I-1430, Lycoming O-1230, H-2470, Pratt & Whitney X-1800/H-2240/2600, H-3130/3730, and the Allison V-1710, X-3420/V-3420 meant that essentially 7 designs were being developed (some of them were reconfigurations and resizing) with little commercial demand in a depression; the result was a massive breadth but little depth to it all.

- The USAAC mostly favored turbochargers over superchargers

- They were sometimes willing to look into two-stage superchargers: The problem was not that they looked into turbochargers (the USN did that too at times), it's that they put turbochargers so far ahead in the running, that secondary stage superchargers were basically in the background not a close or moderate second

- The USN did look into the idea of twin-stage supercharging and made it work with the F4F-3, F4U-1 making their first flights in 1940.

I'm not sure the pilots would've liked that!Regarding the armor plate, keep the rear armor glass and delete the small pieces of armor on the turnover bulkhead (that metal thing protecting the pilot's head).

P-39 Expert

Non-Expert

Makes a lot of sense, there was additional room in the P-63 radiator area for an intercooler if necessary. I like the way Bell got around the intercooler too.It was a liquid to air intercooler, very much like the one on the Merlin, positioned above the engine stage supercharger. This require relocating the carburetor to the intake of the auxiliary supercharger.

The radiator for the intercooler was, presumably, located with or near the engine radiator.

wuzak

Captain

I'm not sure how this would have worked, but I know this configuration was pretty similar and worked on the XB-38...

View attachment 492104

... the problem with the P-37 was the configuration of the radiators producing an excessively long nose.

And the reason for this delay had to do with the fact that

The XB-38 used the standard B-17 turbo location, had a chin mounted intercooler and leading edge radiators (between the nacelles).

Not sure why the standard B-17 intercoolers couldn't be used with a chin mounted radiator - would have made for a simpler conversion - take off the R-1820s and bolt up the V-170 power egg.

Oh, okayIt was a liquid to air intercooler, very much like the one on the Merlin, positioned above the engine stage supercharger. This require relocating the carburetor to the intake of the auxiliary supercharger.

They couldn't fit 1 x 0.50 in each wing?Not sure if the 0.50" mgs could have fitted in the P-39's wings, but if they couldn't it would explain why the 2 x 0.30" mgs in each wing were chosen.

While a little beyond the scope of the P-39 discussion, if the YP-37 had the following repositioned in the following waysThe XB-38 used the standard B-17 turbo location, had a chin mounted intercooler and leading edge radiators (between the nacelles).

- Radiators and intercooler to the wing leading-edges

- Auxiliary fuel tank behind the wing

- Possibly the repositioning of the radio and/or battery behind the cockpit

- Cockpit moved further up

Last edited:

Shortround6

Lieutenant General

One .50 weighs about 3 times what a .30 weighs.

.50 cal ammo weighs 30 lbs per hundred.

.30 cal ammo weighs 6-6.5 lbs per hundred.

If four .30s with 1200 rounds total ruined the P-39 then adding two .50s was hopeless.

Blaming 180 pounds of guns and ammo for ruining plane seems a bit extreme.

.50 cal ammo weighs 30 lbs per hundred.

.30 cal ammo weighs 6-6.5 lbs per hundred.

If four .30s with 1200 rounds total ruined the P-39 then adding two .50s was hopeless.

Blaming 180 pounds of guns and ammo for ruining plane seems a bit extreme.

P-39 Expert

Non-Expert

The 4 x .30caliber wing guns weighed around 377# with 1000rpg (just guns & ammo, not including mounts, chargers, heaters and ammo boxes). Pull all that out and you are looking at 400# weight saved. Later models loaded the .30s with 300rpg to save weight. This reduced the weight of the four guns and ammo to approximately 200# total. So the amount you save depends on the model, either 400# or 200# depending on load.Okay

Stability usually implies a relationship in control surface effectiveness as well as mass...

It is, isn't it?

- How much weight could be trimmed off by removing the 4 x 0.30" and all their ammo?

- How much fuel could be put in that volume

- Would 2 x 0.50 with normal rpg levels add any significant weight?

I'm not sure how this would have worked, but I know this configuration was pretty similar and worked on the XB-38...

View attachment 492104

... the problem with the P-37 was the configuration of the radiators producing an excessively long nose.

And the reason for this delay had to do with the fact that

I'm not sure the pilots would've liked that!

- There was little demand for inline engines in the United States

- The airlines had little interest as air-cooled engines were more reliable; the NACA cowl greatly improved cooling, and reduced drag

- Raceplane designers seemed to vary: The land-based guys used radials almost exclusively because the engines were lighter for the same power, and used very well designed cowlings, and built their planes as light as possible; the seaplane designers usually used liquid cooled or even surface-evaporative cooling and used the struts and braces as radiator surfaces.

- The USN had little interest in inline engines after the late 1920's or early 1930's: Radials were more compact and more reliable, though they were willing, at times, to evaluate inlines if they provided a marked improvement in performance, and as a result funded the Lycoming H-2470, Pratt & Whitney X-1800/H-2240/2600, H-3130/3730

- The USAAC really was the only organization that wanted inline engines, and to this effect, they funded the Continental O-1230/I-1430 Hyper-engine, the V-1710, X-3420/V-3420, and the Lycoming O-1230

- The massive funding of a large number of inline-engines: Including the Continental O-1230/I-1430, Lycoming O-1230, H-2470, Pratt & Whitney X-1800/H-2240/2600, H-3130/3730, and the Allison V-1710, X-3420/V-3420 meant that essentially 7 designs were being developed (some of them were reconfigurations and resizing) with little commercial demand in a depression; the result was a massive breadth but little depth to it all.

- The USAAC mostly favored turbochargers over superchargers

- They were sometimes willing to look into two-stage superchargers: The problem was not that they looked into turbochargers (the USN did that too at times), it's that they put turbochargers so far ahead in the running, that secondary stage superchargers were basically in the background not a close or moderate second

- The USN did look into the idea of twin-stage supercharging and made it work with the F4F-3, F4U-1 making their first flights in 1940.

Fuel where the wing guns were is estimated at 50gal total, 25gal in each wing. Post war racers put 100gal in the same space but were using thin walled tanks instead of the leakproof rubber tanks used in WWII. Estimate is based on measurements. Weight of two .50cal MGs and 300rpg weighed 330# on the P-39Q, but those were hung underneath the wing.

Regarding the P-37, it did result in a long nose. I think reliability of the turbo was the big problem at that stage of the game.

Agree with you completely regarding radial vs inline. For commercial applications radials were superior. Only purpose for an inline engine is for fighter planes IMO.

The small pieces of armor plate in the turnover bulkhead were to either side of the armor glass protecting the pilot's head. That piece of armor glass was large enough to protect the pilot without the small side pieces, so remove them and save the weight. Later models dispensed with the rear armor glass and substituted conventional armor plate to protect the pilot's head like on other bubble canopy planes. Saved a little weight too.

wuzak

Captain

Weight of two .50cal MGs and 300rpg weighed 330# on the P-39Q, but those were hung underneath the wing.

With the wing guns suspended beneath, and not inside, the wing, was any extra fuel carried in the wing of the P-39Q?

Shortround6

Lieutenant General

No.With the wing guns suspended beneath, and not inside, the wing, was any extra fuel carried in the wing of the P-39Q?

The guns were underneath, but the ammo was pretty much in the wing in the old .30 cal ammo storage area.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)