- Thread starter

- #61

Builder 2010

Staff Sergeant

Thanks guys! It's always a test. While sanding and filing the rotor and upper back part, I droppd them on the concrete shop floor. The housing got its nose knocked off, and the rotor lost the small diameter extenision. It's the reason I don't throw away bad parts. I was able to cut the nose off a junker and graft it to the new housing. The fix is undetectable.

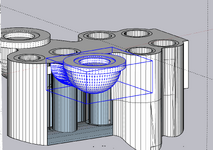

This series shows the evolution of the blade design. To quote Tim Allen in Galaxy Quest, "Never give up, never surrender!" As an eternal optimist I always think there's an answer.

The oblique view shows how nice the big wheel is and that you can perceive blades on all the rest.

I wanted to reprint the now-broken pump-end cap, but inadvertently printed an older version of both ends. The other end actually came out better than the one I kept so I'm exchanging them. The other—the one I wanted—was the wrong version, so I re-set it up on the slicer and will print it later tonight. The improved lower housing is finishing up on the printer right now. That fixes the incorrect profiles I discussed yesterday.

This series shows the evolution of the blade design. To quote Tim Allen in Galaxy Quest, "Never give up, never surrender!" As an eternal optimist I always think there's an answer.

The oblique view shows how nice the big wheel is and that you can perceive blades on all the rest.

I wanted to reprint the now-broken pump-end cap, but inadvertently printed an older version of both ends. The other end actually came out better than the one I kept so I'm exchanging them. The other—the one I wanted—was the wrong version, so I re-set it up on the slicer and will print it later tonight. The improved lower housing is finishing up on the printer right now. That fixes the incorrect profiles I discussed yesterday.