- Thread starter

- #21

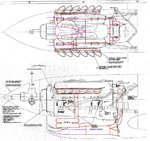

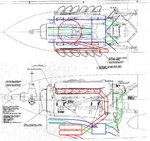

The concept drawing for P-40 high-altitude, developed perhaps after the -C version. Complete installation is in chin, coolers relocated in wings. That, along with loss of hull MGs would've, at least partially, cancel out the shift of CoG after turbo is mounted.

1 (single stage PM : two stage PM : Allison) ratio between P-51 types at hand in mid 1943.

1 (single stage PM : two stage PM : Allison) ratio between P-51 types at hand in mid 1943.