- Thread starter

- #61

Was that also the conclusion of the folks that drove and fought in the radial-powered tanks?It doesn't change - radials aren't the right choice for AFVs.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

Was that also the conclusion of the folks that drove and fought in the radial-powered tanks?It doesn't change - radials aren't the right choice for AFVs.

Hard to say, for the Soviets it was radials vs diesels.Was that also the conclusion of the folks that drove and fought in the radial-powered tanks?

You missed the point, I think.The only new build M36 were the 187 M36B1 built Oct-Dec 1944 on M4A3 hulls, to make up the required contract numbers.

Fisher built 300 turretless M10A1 hulls Dec 1943-Jan 1944 which were used to produce the first M36 with the addition of a new turret with the 90mm gun. Attention then turned to reconditioning M10A1 TD retained with training units in the USA and replacing their turrets. And finally as M10A1s began to run out attention turned in May 1945 to reconditioning diesel engined M10s as the M36B2.

So no opportunity to redo the the M36 drivetrain without spending a lot of money.

Let's throw out the diesel as its tough to compare very different fuels...

They weren't Barbarians, though had to live rough till the first 'civilized' Tank had one from the factory- the Centurion.And a tea kettle, right?

It was a very good boat engine but a 3650lb engine should not be going in a tank.

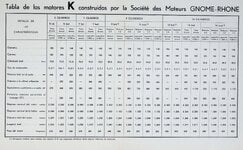

Seeing that, a 14 cyl radial does not look like a bad ideaBack to the theory for more radial engines

The A-57.

a sorta-radial

Seeing that, a 14 cyl radial does not look like a bad idea

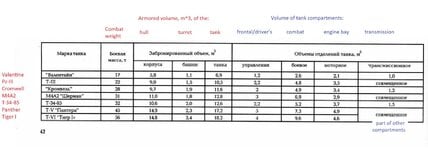

A table taken from the Russian book about ww2 tanks:

View attachment 810310

A few details stand up. Like how he tiny the Valentine was, and especially it's turret. Or, that Cromwell didn't get even the 77mm HV, while the Sherman received the 17pdr despite the small turret. Or, that Panther's turret was just 2/3rds of the volume of the Tiger's turret.

The figures for the turret volume should be just for the 'real' part of the turret, ie. for what is above the hull roof.

The prop shaft that went under the turret basket and the transmission were still eating a lot of volume, even when the 'lowering gearbox' was used.

| Type | Armored | Volume | in M3 | Volume | of | Components | ||

| Combat Weight | Hull | Turret | Total | Driver | Fighting Area | Engine Bay | Transmission | |

| Valentine | 17 | 5.8 | 1.1 | 6.9 | 1.2 | 2.6 | 2.1 | 1 |

| Mk III | 22 | 9 | 1.5 | 10.5 | 2.2 | 4.8 | 3.5 | spread |

| Cromwell | 28 | 9.7 | 1.9 | 11.6 | 2 | 4.9 | 3.4 | 1.3 |

| M4A2 Sherman | 31 | 11 | 1.8 | 12.8 | 3 | 6.9 | 2.9 | spread |

| T-34/85 | 32 | 10.6 | 2 | 12.6 | 2.2 | 5.2 | 3.7 | 1.5 |

| Panther | 45 | 14.9 | 2.3 | 17.2 | 5 | 7.3 | 4.9 | spread |

| Tiger I | 56 | 14.8 | 3.4 | 18.2 | 4 | 9.6 | 4.6 | spread |

That's a strange statement. The Soviets received just under 2000 tanks with radial engines. They produced/received under Lend-Lease many more tanks with inline/V-engines (both carbureted and diesel). Soviet tanks did not have radial engines at all.Hard to say, for the Soviets it was radials vs diesels.

According to the results of the Battle of Kursk, the percentage of losses from fire caused by fuel ignition was about the same for diesel T-34s and gasoline-powered T-70s (the latter were even slightly lower). However, this was rather a consequence of the abominable manufacturing quality of the T-34's fuel lines and the presence of fuel tanks in the crew compartment.A lot of crewmen blamed the fuel for fires and not the ammunition so perceptions are screwed up.

The thing with inline engines is that they are nearly the same length as their Vee derivatives with the same amount of cylinder lengths (eg I6 vs V12, I4 vs V8) - but obviously have only half the power. Or conversely that a Vee engine with the same amount of cylinders will be nearly half as long.

This isn't terribly surprising I suspect, as the largest culprit for tank 'brew ups' were from ammunition and not fuel at all. Still, it's a very intriguing datapoint.That's a strange statement. The Soviets received just under 2000 tanks with radial engines. They produced/received under Lend-Lease many more tanks with inline/V-engines (both carbureted and diesel). Soviet tanks did not have radial engines at all.

According to the results of the Battle of Kursk, the percentage of losses from fire caused by fuel ignition was about the same for diesel T-34s and gasoline-powered T-70s (the latter were even slightly lower). However, this was rather a consequence of the abominable manufacturing quality of the T-34's fuel lines and the presence of fuel tanks in the crew compartment.

For a long time after the war I sought an answer to one question. If a T-34 started burning, we tried to get as far away from it as possible, even though this was forbidden. The on-board ammunition exploded. For a brief period of time, perhaps six weeks, I fought on a T-34 around Smolensk. The commander of one of our companies was hit in his tank. The crew jumped out of the tank but were unable to run away from it because the Germans were pinning them down with machine gun fire. They lay there in the wheat field as the tank burned and blew up. By evening, when the battle had waned, we went to them. I found the company commander lying on the ground with a large piece of armor sticking out of his head. When a Sherman burned, the main gun ammunition did not explode. Why was this?

Such a case occurred once in Ukraine. Our tank was hit. We jumped out of it but the Germans were dropping mortar rounds around us. We lay under the tank as it burned. We laid there a long time with nowhere to go. The Germans were covering the empty field around the tank with machine gun and mortar fires. We lay there. The uniform on my back was beginning heating up from the burning tank. We thought we were finished! We would hear a big bang and it would all be over! A brother's grave! We heard many loud thumps coming from the turret. This was the armor-piercing rounds being blown out of their cases. Next the fire would reach the high explosive rounds and all hell would break loose! But nothing happened. Why not? Because our high explosive rounds detonated and the American rounds did not? In the end it was because the American ammunition had more refined explosives. Ours was some kind of component that increased the force of the explosion one and one-half times, at the same time increasing the risk of detonation of the ammunition.

US Tanks tended to use hydraulic motor for turret traverse, powered by electric pump- though some Shermans were direct Electric driveThis isn't terribly surprising I suspect, as the largest culprit for tank 'brew ups' were from ammunition and not fuel at all. Still, it's a very intriguing datapoint

Normally, the secondary fragments ignite the fuel first, and then the munition detonates from the fire - only in the case of a shaped charge projectile the munition may detonate earlier. I was talking about statistics of tanks burned, not destroyed by internal explosion - those causes were considered separately AFAIK. It was fuel ignition that was the cause of tank loss. Due to poor workmanship and/or poor design of the T-34's fuel lines, which could not withstand the vibration and shaking when moving, fuel often leaked into the crew compartment. It could form puddles and soak tankers' clothes or rags - gasoline would evaporate in such conditions, while diesel fuel would not. And if it caught fire, it was more difficult to put it out than burning gasoline. As a result, the theoretically more fire-safe diesel tank revealed no difference from the theoretically more dangerous gasoline one.This isn't terribly surprising I suspect, as the largest culprit for tank 'brew ups' were from ammunition and not fuel at all. Still, it's a very intriguing datapoint.

The cases (known to me) where a large percentage of tank losses were caused by exploding ammunition (e.g., the Rechitsa offensive) are related to the mass use of shaped charge shells/ mines/grenades. If the main losses were inflicted by AT artillery using conventional AP shells, ammunition explosions were much less frequent.Also worth noting in this regard the typical T-34, despite being diesel-fueled, had relatively sensitive propellants and charges for its ammunition, which resulted in fairly catastrophic conflagration or detonation upon the tank brewing up.

I read the book by Dmitry Loza, as well as many other recollections/books of Soviet tankers/self-propelled artillery men.Colonel Loza had some very interesting recollections on such instances,

I read several very detailed Soviets reports with the analysis of the Soviet armor losses.Also, I highly recommend for folks use and reference of the ORO-T-117 armor casualty report

Normally, the secondary fragments ignite the fuel first, and then the munition detonates from the fire

It's quite an interesting perspective on many things, the recommendation was more for other folks though as I've little doubt you would've.I read the book by Dmitry Loza, as well as many other recollections/books of Soviet tankers/self-propelled artillery men.

Indeed, I don't mean to imply that you haven't--consider it as a remark for the 'audience' and just as a useful resource which folks may find useful in these discussions. It certainly compiles a lot of datapoints and datasets.I read several very detailed Soviets reports with the analysis of the Soviet armor losses.

Exactly. It was a specific problem of the T-34 -. in addition to many others. But I assume it rather as a technological bug, not the flaw of the concept. There were almost no cases of ammunition exploding in T-70 tanks. In addition, there was a special study of the explosiveness of fuel in fuel tanks, it was found that diesel fuel tends to explode if fuel tank is near to empty, enhancing the effect of an armor-piercing projectile - I have also mentioned this on this forum before.What's interesting is that this contrasts with the US & UK experiences. But, I suspect from your remarks, this may be more of a factor due to the fuel tank location on vehicles like the T-34, which includes such within the fighting compartment.

There is no mystery about this: the T-34 was widely used before the Germans began using shaped charges on a large scale. And losses from shaped charges could vary greatly in different operations depending on the conditions, and even more so on the experience of tank unit commanders.The curious flip is that the US noted most fuel fires were from shaped charge, I suspect due to the prevalence of Panzerfausts and similar, which ORO-T-117 indicated they had a preference towards targeting the engine bay--presumably to guarantee a mission kill with their disposable launcher.

This is definitely an excellent recommendation, Dmitry Loza's book deserves the most careful reading, I just wanted to say that I took his opinion into account. But his view and experience is not enough for objective assessments of Soviet tanks. I have emphasized many times on this forum the difficulty of evaluating Soviet equipment - high losses were too often due to insufficient training of crews and unit commanders, not to shortcomings of tanks/planes/etc.It's quite an interesting perspective on many things, the recommendation was more for other folks though as I've little doubt you would've.

This is a great information source (I mean the ORO-T-117 report), thank you! But one should always keep in mind that Soviet technology was highly specific due to the peculiarities of Soviet industry (mainly weakness and lack of flexibility). So you can't extrapolate Western data to Soviet equipment in general. Although, of course, exceptions can be found.Indeed, I don't mean to imply that you haven't--consider it as a remark for the 'audience' and just as a useful resource which folks may find useful in these discussions. It certainly compiles a lot of datapoints and datasets.

| DETAIL OF THE CHARACTERISTICS | 5 CYLINDERS | 5 CYLINDERS | 5 CYLINDERS | 7 CYLINDERS | 7 CYLINDERS | 7 CYLINDERS | 9 CYLINDERS | 9 CYLINDERS | 9 CYLINDERS | 9 CYLINDERS | 9 CYLINDERS | 9 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS | 14 CYLINDERS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specifications | 5 k.d. | 5 k.s.d. | 5 k.s.d. | 7 k.d. | 7 k.s.d. | 7 k.s.d. | 9 k.r.d. (1) | 9 k.r.d. (1) | 9 k.r.s.d. (1) | 9 k.r.s.d. (1) | 9 k.r.s.d. (1) | 9 k.r.s.d. (1) | 14 k.r.d. (1) | 14 k.r.d. (1) | 14 k.s.d. | 14 k.s.d. | 14 k.r.s.d. (1) | 14 k.r.s.d. (1) | 14 k.r.s.d. (1) | 14 k.r.s.d. (1) |

| Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Direct Drive | Geared 2/3 | Geared 1/2 | Geared 2/3 | Geared 2/3 | Geared 1/2 | Geared 1/2 | Geared 2/3 | Geared 1/2 | Direct Drive | Direct Drive | Geared 2/3 | Geared 2/3 | Geared 1/2 | Geared 1/2 | |

| normal | 1,500 m | 4,000 m | normal | 1,500 m | 4,000 m | Normal | Normal | 1,500 m | 4,000 m | 1,500 m | 4,000 m | Normal | Normal | 1,500 m | 4,000 m | 1,500 m | 4,000 m | 1,500 m | 4,000 m | |

| Diameter... | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 |

| Stroke... | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 |

| Total displacement... liters | 13.8 | 13.8 | 13.8 | 19.3 | 19.3 | 19.3 | 24.8 | 24.8 | 24.8 | 24.8 | 24.8 | 24.8 | 38.6 | 38.6 | 38.6 | 38.6 | 38.6 | 38.6 | 38.6 | 38.6 |

| Compression ratio | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 | 5.5/1 |

| Total power on the ground... HP | 240 | 240 | 220 | 350 | 350 | 320 | 500 | 500 | 500 | 450 | 500 | 450 | 800 | 800 | 750 | 650 | 780 | 680 | 780 | 680 |

| Power at operational altitude... HP | - | 255 | 235 | - | 365 | 340 | - | - | 530 | 500 | 530 | 500 | - | - | 825 | 740 | 825 | 740 | 825 | 740 |

| Ground power equivalence... HP | 270 | 300 | 370 | 380 | 425 | 540 | 550 | 550 | 620 | 790 | 620 | 790 | 870 | 870 | 970 | 1,170 | 970 | 1,170 | 970 | 1,170 |

| Maximum allowed power for takeoff (5')... HP | - | 265 | 240 | - | 380 | 350 | - | - | 565 | 520 | 565 | 520 | - | - | 840 | 700 | 830 | 690 | 830 | 690 |

| Nominal engine speed... rpm | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,300 | 2,400 | 2,400 | 2,300 | 2,300 | 2,400 | 2,400 | 2,400 | 2,400 |

| Nominal propeller speed... rpm | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,530 | 1,150 | 1,530 | 1,530 | 1,150 | 1,150 | 1,600 | 1,200 | 2,300 | 2,300 | 1,600 | 1,600 | 1,200 | 1,200 |

| Total engine diameter... meters | 1.207 | 1.207 | 1.207 | 1.235 | 1.235 | 1.235 | 1.299 | 1.299 | 1.299 | 1.299 | 1.299 | 1.299 | 1.288 | 1.288 | 1.288 | 1.288 | 1.288 | 1.288 | 1.288 | 1.288 |

| Total length... meters | 1.010 | 1.035 | 1.035 | 1.050 | 1.075 | 1.075 | 1.297 | 1.295 | 1.325 | 1.325 | 1.325 | 1.325 | 1.530 | 1.528 | 1.317 | 1.317 | 1.556 | 1.556 | 1.554 | 1.554 |

| Engine weight... kilograms | 213 | 222 | 222 | 270 | 281 | 281 | 360 | 355 | 374 | 374 | 369 | 369 | 508 | 503 | 502 | 502 | 528 | 528 | 523 | 523 |