Skyediamonds

Staff Sergeant

- 1,226

- May 26, 2018

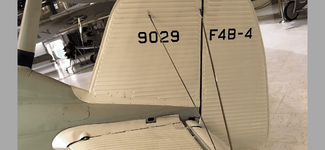

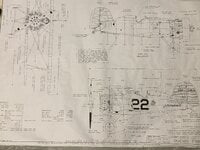

Good afternoon everyone. I'm in the middle of scratching out a wooden 1/10th scale 36" top wingspan Boeing F4B-4. It's for display & will ultimately be given to my son.

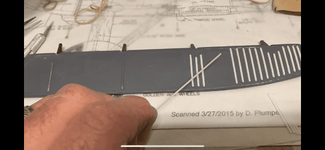

Both wings are framed up & waiting to be covered. The corrugated tail feathers & ailerons are finished & waiting to be installed.

All that remains is the fuselage & it's associated cabane & landing gear struts & of course all of the accessories & attachments.

I'll start this modeling post with a couple of photos of the fuselage as it stands as of July 9, 2024.

Both wings are framed up & waiting to be covered. The corrugated tail feathers & ailerons are finished & waiting to be installed.

All that remains is the fuselage & it's associated cabane & landing gear struts & of course all of the accessories & attachments.

I'll start this modeling post with a couple of photos of the fuselage as it stands as of July 9, 2024.