This kind of points out the problem with the Sten gun school of aircraft design.

If you want to use the same power plant and armament of the standard/first line fighters you have already spent 46.6% of the total cost.

If you can reduce the cost of the airframe by 20% your Sten fighter will cost about 89.49% as much as the standard fighter. Is that "savings" worth it? as in pay for the new tooling, duplication of supply, etc.

Sten was not just about price being low (that certainly helped), but also about the ability to make them in big quantities for a major war that was to swallow man and material alike. Eg. neither of the 3 Italian fighter producers, whose series-produced fighters were worth talking about (Fiat, Macchi, Regianne), was not offering a fast-to-manufacture A/C.

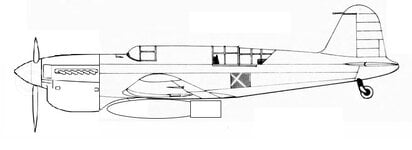

Eg. see here for the MC.202, particularly the wings - each rib was a built-up piece, making the aircraft taking much more manhours than what would a wing that had stamped 1-piece ribs, as in case of Bf 109 for example.

High manhour cost was noted by the Germans when they were testing the '5 series' fighters, looking to perhaps make the best of them in Germany.

Now if you can use a cheaper engine things get a bit more attractive at first glance but then you are very likely to loose performance. French were pretty good at keeping the speed up. Climb, cockpit view, field performance not so much.

You can get some of the performance back and save money by using less armament.

Money can be saved with less operations and manhours needed to make the A/C in quantities needed.

MS.406 was bad in keeping speed up, and 'good' in keeping the manhour cost high. French aircraft designers didn't have 1000+ HP engines to make their fighter perform, either.

Spitfire, despite it's high manhour cost, was also with bad forward visibility