syscom3

Pacific Historian

The Future of Things (TFOT) - Engine on a Chip – the Dream of the Personal Turbine

After a decade of work, the first millimeter size turbine engine developed by researchers at MIT should become operational by the end of this summer. The new turbine engine will allow the creation of smaller and more powerful batteries than anything currently in existence. It might also serve as the basis for tiny powerful motors with applications ranging from micro UAVs to children's toys. In the more distant future huge arrays of hydrogen fueled millimeter turbine engines could even be the basis for clean, quiet and cost effective power plants. Turbine engine history

Turbine engine history goes back to the beginning of the 20'th century. In 1903 the Norwegian inventor Aegidus Elling became the first person to successfully construct a gas turbine engine which produced excess power, reaching 11hp (the Wright brothers Kitty Hawk which flew for the first time that year had 12hp). Several years later Charles Curtis, who invented the Curtis steam engine, filed the first patent application in the U.S. for a gas turbine engine which he was granted in 1914 (but not without some controversy). Four years later, in 1918, General Electric (GE), founded by Edison in the mid 1870's, started work on aircraft engine turbochargers and two decades later on aircraft jet engines on their gas turbine division (now one of the biggest in the world). In 1930 the inventor and Royal Air Force officer Sir Frank Whittle, building on previous work including that of Elling, designed and patented the first gas turbine for jet propulsion. After a neck to neck race to build the first jet powered engine, the German Hans von Ohain, working with the Heinkel Company, became the first to design and test a jet powered aircraft in 1939 beating Whittle which suffered from technical problems with his design.

After the war turbine jet engines continued to develop and grow in size and power forming the basis for almost all modern aircraft engines. Holding the world record today is the GE90 series engine which helps power the Boeing 777 Airliner. With 22 blades the engine is over 120 inch (3 meters) tall producing over 115,000lb of thrust (over 127,000lb on a test) this engine is 10,000 more powerful than that used by the Wright brothers one century ago.

Enormous gas turbine engines are also used for electrical power production. In a gas turbine (also known as combustion-turbine), hot gases produced from the combustion of natural gas in a high-pressure combustion chamber are passed through the turbine, which spins the generator to produce electricity. Gas turbines are commonly used to serve the peak loads of the electric utility and have grown in size and complexity over the years. Simens' SGT5-8000H advanced gas turbine engine, the alleged world record holder, is a gigantic machine weighing over 440 tons (880,000 pound) and able to reach an output of 340 MW in simple cycle and about twice as much in a combined cycle. The efficiency of the SGT5-8000H is almost 40% and around 60% in combined cycle.

Beside airplanes and power plants gas turbine engines have many other uses, ranging from tank engines (gas turbine engine is used in the M1A1 Abrams tank), ship and locomotive engines as well as auxiliary power units. But beside those large scale solutions, new technology has allowed smaller and smaller versions of gas turbines. IHI Aerospace in Japan developed a small portable gas turbine generator called Dynajet 2.6, which produces 2.6 kW and has a total weight of 67 kilograms. A different micro sized gas turbine was developed by researchers at the Swiss Federal Institute of Technology (ETH Zurich). This tiny turbine reached a size of several centimeters producing up to 100 watts of electricity for a period of several days. Pushing the technology even further, researchers at the Massachusetts Institute of Technology developed the building blocks for an even smaller gas turbine engine with a size of about 1 mm which they hope will be fully assembled and functioning before the end of 2007.

Although it might be hard to see the resemblance between a giant like the GE90 and the millimeter scale engine being developed at MIT, they actually have quite a bit in common with each other. A gas turbine, both large and small consists of a compressor, a combustion chamber, and a turbine that is driven by the combustion exhaust and powers the compressor. Upon start-up, fuel is injected at the compressor exit, mixes with air, ignites and escapes in high pressure through the exhaust, spinning the turbine which is used to power the generator producing the electricity.

Producing a millimeter size turbine engine also poses some unique challenges which conventional gas turbines do not face. To understand some of them we need to understand more about the new MIT millimeter turbine engine design.

Going micro

MIT millimeter turbine - same components as a macro sized turbine

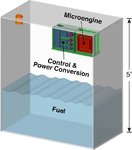

The millimeter size turbine engine project in MIT started in the middle of the 1990's when Professor of Aeronautics and Astronautics Alan H. Epstein considered the possibility of creating a personal turbine which will be able to meet all the demands of a modern person's electrical needs, just like a large turbine can meet the electricity demands of a small city.

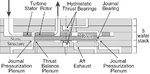

Millimeter turbine engine - conceptual cross-section

The millimeter turbine has the same components as a macro sized conventional turbine engine, but their size requires an entirely different manufacturing technology. According to Professor Epstein, millimeter sized turbines also have many of the same design considerations as large turbines including basic layout, mechanical stress, oxidation-limit etc. In some respects designing a micro size turbine is simpler than a conventional macro one since the microrotors of the turbine are very stiff, eliminating bending problems which occur on larger rotors. Thermal stress is also not an issue at these sizes as well as maintenance of any kind (you will never fix a micro turbine but simply replace the entire engine).

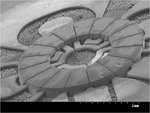

The millimeter turbine technology is based on semiconductor manufacturing techniques. This enables the fabrication of complex micro parts and assemblies – devices with dimensions in the 1-10,000 micron size range with submicron precision. Such parts are produced with photolithographically-defined features and many can be made simultaneously, offering the promise of low production costs in large-scale production.

Millimeter size turbine engine - Semiconductor manufacturing techniques

The main fabrication processes used in the creation of the millimeter turbine components is etching of photolithographically-defined planar geometries and bonding of multiple wafers. According to Epstein, the usual starting point is a flat wafer of the base material, usually single-crystal silicon. These wafers are typically 0.5 to 1.0 mm thick and 100 to 300 mm in diameter, the larger size representing a more modern technology. Dozens to hundreds of micro sized turbine engines can fit on a single wafer. Ideally, the processing of all the devices on a wafer is carried out in parallel, leading to one of the great advantages of this micromachining approach, low unit cost.

First, the wafers are coated with a light-sensitive photoresist. A high contrast black-and-white pattern defining the geometry is then optically transferred to the resist either by means of a contact exposure with a glass plate containing the pattern (a "mask"), or by direct optical or e-beam writing. The photoresist is then chemically developed as though it was photographic film, baked, and then the exposed areas are removed with a solvent. This leaves bare silicon in the areas to be etched and photoresist-protected silicon elsewhere. The etching process is based on the principle that the bare silicon is etched at a much higher rate, typically 50-100x, than the mask material. Many different options for making masks have been developed, including a wide variety of photoresists and various oxide or metal films. By using several layers of masking material, each sensitive to different solvents, multi-depth structures can be defined. Photoresist on top of SiO2 is one example.

The millimeter size turbine has many possible applications ranging from military to civilian and industrial. The millimeter turbine project in MIT is currently funded by the U.S. military which sees a great potential for this upcoming technology. Anything from small unmanned aerial vehicles (UAVs) to a soldier night scope can be operated by a tiny refuelable turbine powered by a small protected hydrogen fuel cartridge. Another interesting possible use of the millimeter turbine engine is the exoskeleton, a technology currently under development which will enable future soldiers to carry tremendous weights across great distances with little effort. Current exoskeleton prototypes suffer from a range of problems limiting their usefulness. They are big, heavy, cumbersome and restricting as well as very complex and expensive to make. Using millimeter turbine engines to power the exoskeleton can save space, weight, reduce costs and extend the unit operational time. If several millimeter engines could also be used to move the joints of the exoskeleton, and not only be used as a power source for larger motors, they might also potentially allow for a much quieter operation (a disadvantage of most existing exoskeleton systems).

After a decade of work, the first millimeter size turbine engine developed by researchers at MIT should become operational by the end of this summer. The new turbine engine will allow the creation of smaller and more powerful batteries than anything currently in existence. It might also serve as the basis for tiny powerful motors with applications ranging from micro UAVs to children's toys. In the more distant future huge arrays of hydrogen fueled millimeter turbine engines could even be the basis for clean, quiet and cost effective power plants. Turbine engine history

Turbine engine history goes back to the beginning of the 20'th century. In 1903 the Norwegian inventor Aegidus Elling became the first person to successfully construct a gas turbine engine which produced excess power, reaching 11hp (the Wright brothers Kitty Hawk which flew for the first time that year had 12hp). Several years later Charles Curtis, who invented the Curtis steam engine, filed the first patent application in the U.S. for a gas turbine engine which he was granted in 1914 (but not without some controversy). Four years later, in 1918, General Electric (GE), founded by Edison in the mid 1870's, started work on aircraft engine turbochargers and two decades later on aircraft jet engines on their gas turbine division (now one of the biggest in the world). In 1930 the inventor and Royal Air Force officer Sir Frank Whittle, building on previous work including that of Elling, designed and patented the first gas turbine for jet propulsion. After a neck to neck race to build the first jet powered engine, the German Hans von Ohain, working with the Heinkel Company, became the first to design and test a jet powered aircraft in 1939 beating Whittle which suffered from technical problems with his design.

After the war turbine jet engines continued to develop and grow in size and power forming the basis for almost all modern aircraft engines. Holding the world record today is the GE90 series engine which helps power the Boeing 777 Airliner. With 22 blades the engine is over 120 inch (3 meters) tall producing over 115,000lb of thrust (over 127,000lb on a test) this engine is 10,000 more powerful than that used by the Wright brothers one century ago.

Enormous gas turbine engines are also used for electrical power production. In a gas turbine (also known as combustion-turbine), hot gases produced from the combustion of natural gas in a high-pressure combustion chamber are passed through the turbine, which spins the generator to produce electricity. Gas turbines are commonly used to serve the peak loads of the electric utility and have grown in size and complexity over the years. Simens' SGT5-8000H advanced gas turbine engine, the alleged world record holder, is a gigantic machine weighing over 440 tons (880,000 pound) and able to reach an output of 340 MW in simple cycle and about twice as much in a combined cycle. The efficiency of the SGT5-8000H is almost 40% and around 60% in combined cycle.

Beside airplanes and power plants gas turbine engines have many other uses, ranging from tank engines (gas turbine engine is used in the M1A1 Abrams tank), ship and locomotive engines as well as auxiliary power units. But beside those large scale solutions, new technology has allowed smaller and smaller versions of gas turbines. IHI Aerospace in Japan developed a small portable gas turbine generator called Dynajet 2.6, which produces 2.6 kW and has a total weight of 67 kilograms. A different micro sized gas turbine was developed by researchers at the Swiss Federal Institute of Technology (ETH Zurich). This tiny turbine reached a size of several centimeters producing up to 100 watts of electricity for a period of several days. Pushing the technology even further, researchers at the Massachusetts Institute of Technology developed the building blocks for an even smaller gas turbine engine with a size of about 1 mm which they hope will be fully assembled and functioning before the end of 2007.

Although it might be hard to see the resemblance between a giant like the GE90 and the millimeter scale engine being developed at MIT, they actually have quite a bit in common with each other. A gas turbine, both large and small consists of a compressor, a combustion chamber, and a turbine that is driven by the combustion exhaust and powers the compressor. Upon start-up, fuel is injected at the compressor exit, mixes with air, ignites and escapes in high pressure through the exhaust, spinning the turbine which is used to power the generator producing the electricity.

Producing a millimeter size turbine engine also poses some unique challenges which conventional gas turbines do not face. To understand some of them we need to understand more about the new MIT millimeter turbine engine design.

Going micro

MIT millimeter turbine - same components as a macro sized turbine

The millimeter size turbine engine project in MIT started in the middle of the 1990's when Professor of Aeronautics and Astronautics Alan H. Epstein considered the possibility of creating a personal turbine which will be able to meet all the demands of a modern person's electrical needs, just like a large turbine can meet the electricity demands of a small city.

Millimeter turbine engine - conceptual cross-section

The millimeter turbine has the same components as a macro sized conventional turbine engine, but their size requires an entirely different manufacturing technology. According to Professor Epstein, millimeter sized turbines also have many of the same design considerations as large turbines including basic layout, mechanical stress, oxidation-limit etc. In some respects designing a micro size turbine is simpler than a conventional macro one since the microrotors of the turbine are very stiff, eliminating bending problems which occur on larger rotors. Thermal stress is also not an issue at these sizes as well as maintenance of any kind (you will never fix a micro turbine but simply replace the entire engine).

The millimeter turbine technology is based on semiconductor manufacturing techniques. This enables the fabrication of complex micro parts and assemblies – devices with dimensions in the 1-10,000 micron size range with submicron precision. Such parts are produced with photolithographically-defined features and many can be made simultaneously, offering the promise of low production costs in large-scale production.

Millimeter size turbine engine - Semiconductor manufacturing techniques

The main fabrication processes used in the creation of the millimeter turbine components is etching of photolithographically-defined planar geometries and bonding of multiple wafers. According to Epstein, the usual starting point is a flat wafer of the base material, usually single-crystal silicon. These wafers are typically 0.5 to 1.0 mm thick and 100 to 300 mm in diameter, the larger size representing a more modern technology. Dozens to hundreds of micro sized turbine engines can fit on a single wafer. Ideally, the processing of all the devices on a wafer is carried out in parallel, leading to one of the great advantages of this micromachining approach, low unit cost.

First, the wafers are coated with a light-sensitive photoresist. A high contrast black-and-white pattern defining the geometry is then optically transferred to the resist either by means of a contact exposure with a glass plate containing the pattern (a "mask"), or by direct optical or e-beam writing. The photoresist is then chemically developed as though it was photographic film, baked, and then the exposed areas are removed with a solvent. This leaves bare silicon in the areas to be etched and photoresist-protected silicon elsewhere. The etching process is based on the principle that the bare silicon is etched at a much higher rate, typically 50-100x, than the mask material. Many different options for making masks have been developed, including a wide variety of photoresists and various oxide or metal films. By using several layers of masking material, each sensitive to different solvents, multi-depth structures can be defined. Photoresist on top of SiO2 is one example.

The millimeter size turbine has many possible applications ranging from military to civilian and industrial. The millimeter turbine project in MIT is currently funded by the U.S. military which sees a great potential for this upcoming technology. Anything from small unmanned aerial vehicles (UAVs) to a soldier night scope can be operated by a tiny refuelable turbine powered by a small protected hydrogen fuel cartridge. Another interesting possible use of the millimeter turbine engine is the exoskeleton, a technology currently under development which will enable future soldiers to carry tremendous weights across great distances with little effort. Current exoskeleton prototypes suffer from a range of problems limiting their usefulness. They are big, heavy, cumbersome and restricting as well as very complex and expensive to make. Using millimeter turbine engines to power the exoskeleton can save space, weight, reduce costs and extend the unit operational time. If several millimeter engines could also be used to move the joints of the exoskeleton, and not only be used as a power source for larger motors, they might also potentially allow for a much quieter operation (a disadvantage of most existing exoskeleton systems).