- Thread starter

- #61

Skyediamonds

Staff Sergeant

- 1,362

- May 26, 2018

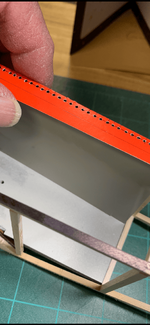

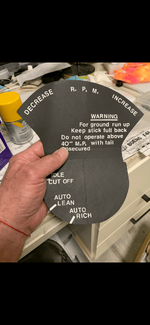

Next, the holes to the cardstock were measured & a small modeler's punch & die set was used to create holes.

Unlike the plastic strips, paper doesn't take to drills without making a mess with paper fibers scattered around the drilled holes.

The cardstock was then given final measurements & cut to size.

Unlike the plastic strips, paper doesn't take to drills without making a mess with paper fibers scattered around the drilled holes.

The cardstock was then given final measurements & cut to size.