- Thread starter

- #121

Skyediamonds

Staff Sergeant

- 1,362

- May 26, 2018

Continuing on:

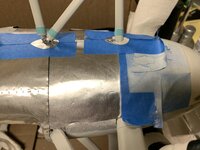

After the wax paper was laid over the wing & taped down, the blue masking tapes with the base of the fairing cutouts were then laid down on either side of the strut -making sure the cutout matched.

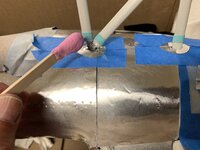

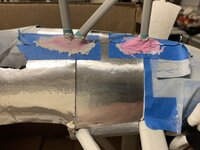

Once everything was in place, I poured a resin mix. Resin was used at the base to ensure a strong fairing-to-wing join.

Before the resin started to cure, I quickly peeled back the masking tapes, making sure that none of the resin spilled over.

After the wax paper was laid over the wing & taped down, the blue masking tapes with the base of the fairing cutouts were then laid down on either side of the strut -making sure the cutout matched.

Once everything was in place, I poured a resin mix. Resin was used at the base to ensure a strong fairing-to-wing join.

Before the resin started to cure, I quickly peeled back the masking tapes, making sure that none of the resin spilled over.