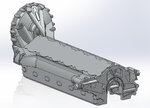

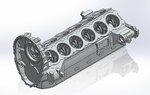

I haven't had a lot of time to do something fun like this so I've actually been working on the project on the side for a couple of years now and haven't made tons of progress, but with covid and losing my job I have more time for it, so I have enough to actually show off a little. The model itself and the rendering are done in SolidWorks. The drawings are from AircorpsLibrary. I've completed 3 top level subassemblies now and am working on the fourth. This one is the largest and most complex I've worked on in the project so far. I'll post each one individually so as to make things easier to delineate, but the images are kinda large, so just a heads up.

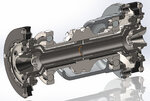

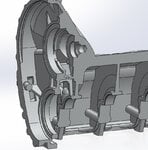

The first project I did was the starter, it was done back in late 2018. The only parts that are missing are the windings (or a reasonable facsimile of them) because I didn't have a drawing for them. There is a part number and drawing for them, I just didn't have a copy. I'm also missing the nameplate because I didn't want to deal with creating a decal wrap for the surface. I'll probably them some day IO have more time... oh... wait. teehee

teehee

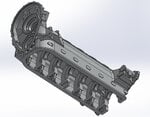

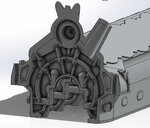

If any of you know anything about solidworks, and cad in general, they don't do gears very easily. I had to learn a lot, it was a steep curve, but I can say these gears are machinable models. (kinda proud of that fact)

Give me a few and I'll get the rest of the subassemblies posted.

The first project I did was the starter, it was done back in late 2018. The only parts that are missing are the windings (or a reasonable facsimile of them) because I didn't have a drawing for them. There is a part number and drawing for them, I just didn't have a copy. I'm also missing the nameplate because I didn't want to deal with creating a decal wrap for the surface. I'll probably them some day IO have more time... oh... wait.

If any of you know anything about solidworks, and cad in general, they don't do gears very easily. I had to learn a lot, it was a steep curve, but I can say these gears are machinable models. (kinda proud of that fact)

Give me a few and I'll get the rest of the subassemblies posted.