- Thread starter

- #161

Builder 2010

Staff Sergeant

That's kind of poetic isn't it.

Last Wednesday was my wife's 3rd of 4 chemo infusions. With the revised dosage, things are considerably better than the first session, but chemo is still awful. By attacking all cells in your body that replicate more frequently, it affects all mucous membranes, the linings of your entire alimentary canal, taste buds, lining of the mouth, and of course hair follicles. But with all that, she's doing pretty well and the end is in sight.

My sister sent me an article in the Philadelphia Inquirer that described and entirely new vaccine approach to enable people with the BRCA 2 genetic mutation to effectively fight nascent cancer cells. BRCA mutations do not cause cancer. They eliminate one of the body's natural defenses to kill them when they're going rogue. This vaccine, now in human testing, injects DNA into the white cells that identify cells that are cheating by extending their telomeres at the end of the gene, thereby granting the cell immortality, when it should have died. It's one of the cancer cells tricks to do what it does. It's a novel approach that offers great promise.

All of this medical stuff has reduced my model building. That said, I'm still doing something.

Today, that something was to glue the gun house together, sand and then fill all of the gaps and discontinuities, secure the wiring harness, and get it ready for painting. Too bad I wasn't further along because today was a wonderful day to paint outside… 72 degrees, sunny and fairly calm breeze. Alas, the paint will still have to wait until the GH is fully prepped.

Gluing was a delicate operation. I had to avoid clamping too hard and keep away from the ladder rungs and the gun sight on the roof. As it is I did whack a couple more rungs. No big deal. I just drill them out and replace them. I guess I should have waited until all the sanding and filling was done… 20/20 hindsight. *"If my foresight was as good as my hindsight, I'd be better by a darn

sight!"*

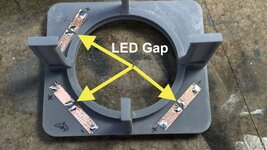

After the glue up was secure and I sanded the joints to level them, I secured the LED wiring inside. I'm running the three LEDs in series so one set of red and black leads will be tied together, It was too cramped and awkward to attempt the splice inside the gun house. Instead, I'm running all four leads out, splicing them and then running them into the upper handling room. Again, I used Bondic as liquid cable clamps.

I was then able to apply some Bondic to close any larger gaps and finish up with Tamiya Fine Putty. After curing overnight I'll do the finish sanding, fix any broken rungs and get it primed. Don't know what tomorrow's weather portends yet. I'll have to check.

I also have some bolt heads to add to the sides to line up with the framing members that lie underneath. I added these on the print, but the sides are sheet styrene. In retrospect I could have printed all of the gun house flat surfaces considering how well the upper handling room walls came out.

Speaking of the UHR, I glued three of the four walls together with thin CA and accelerator. All along I've been assuming that I'll just leave off the front wall, but I rethinking that. I may want to install it and then cutaway some for viewing.

Last Wednesday was my wife's 3rd of 4 chemo infusions. With the revised dosage, things are considerably better than the first session, but chemo is still awful. By attacking all cells in your body that replicate more frequently, it affects all mucous membranes, the linings of your entire alimentary canal, taste buds, lining of the mouth, and of course hair follicles. But with all that, she's doing pretty well and the end is in sight.

My sister sent me an article in the Philadelphia Inquirer that described and entirely new vaccine approach to enable people with the BRCA 2 genetic mutation to effectively fight nascent cancer cells. BRCA mutations do not cause cancer. They eliminate one of the body's natural defenses to kill them when they're going rogue. This vaccine, now in human testing, injects DNA into the white cells that identify cells that are cheating by extending their telomeres at the end of the gene, thereby granting the cell immortality, when it should have died. It's one of the cancer cells tricks to do what it does. It's a novel approach that offers great promise.

All of this medical stuff has reduced my model building. That said, I'm still doing something.

Today, that something was to glue the gun house together, sand and then fill all of the gaps and discontinuities, secure the wiring harness, and get it ready for painting. Too bad I wasn't further along because today was a wonderful day to paint outside… 72 degrees, sunny and fairly calm breeze. Alas, the paint will still have to wait until the GH is fully prepped.

Gluing was a delicate operation. I had to avoid clamping too hard and keep away from the ladder rungs and the gun sight on the roof. As it is I did whack a couple more rungs. No big deal. I just drill them out and replace them. I guess I should have waited until all the sanding and filling was done… 20/20 hindsight. *"If my foresight was as good as my hindsight, I'd be better by a darn

sight!"*

After the glue up was secure and I sanded the joints to level them, I secured the LED wiring inside. I'm running the three LEDs in series so one set of red and black leads will be tied together, It was too cramped and awkward to attempt the splice inside the gun house. Instead, I'm running all four leads out, splicing them and then running them into the upper handling room. Again, I used Bondic as liquid cable clamps.

I was then able to apply some Bondic to close any larger gaps and finish up with Tamiya Fine Putty. After curing overnight I'll do the finish sanding, fix any broken rungs and get it primed. Don't know what tomorrow's weather portends yet. I'll have to check.

I also have some bolt heads to add to the sides to line up with the framing members that lie underneath. I added these on the print, but the sides are sheet styrene. In retrospect I could have printed all of the gun house flat surfaces considering how well the upper handling room walls came out.

Speaking of the UHR, I glued three of the four walls together with thin CA and accelerator. All along I've been assuming that I'll just leave off the front wall, but I rethinking that. I may want to install it and then cutaway some for viewing.