Nice work so far!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stripped down Mosquito MK IV 1/32

- Thread starter BertUS

- Start date

Ad: This forum contains affiliate links to products on Amazon and eBay. More information in Terms and rules

More options

Who Replied?- Thread starter

- #302

BertUS

Senior Airman

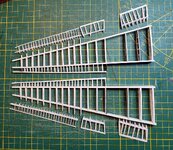

It's time for some free work again, so I've started on the airlerons, before I start adding all kinds of details in the wing and I can't reach anything anymore

So I work a little bit off the wing of the Revell model, because although I have a number of drawings, they still differ from each other, especially in terms of dimensions. So you have to assume something and that's why I chose the Revell model (the HK model is nicer, but to buy a reference thing for 160 euros now, mwah, the Harley just got through it here in the house )

)

Anyway, the first step is often the drawing work

Then cut a batch

and paste

What's the difference with making tracks for a tank?

Tightening and holding on fragile things when I do this I use a very specialist clamp that I can adjust to press force, I work with purely simple tools but this was well worth the investment

Well, then you have a staircase that still needs to be sanded into shape, and that has to be done with care, because before you know it the ribs will shoot in every direction again

But perseverance wins and you still get something of this, still had to cut some loose and realign, but okay, for the time being these can harden for a while, then put the crossheads on and think about how they can be attached to the wing, movable of course

Well, I'll continue with the flaps, that's easy to write over, just CTRL C and CTRL V of the text, just different places

So I work a little bit off the wing of the Revell model, because although I have a number of drawings, they still differ from each other, especially in terms of dimensions. So you have to assume something and that's why I chose the Revell model (the HK model is nicer, but to buy a reference thing for 160 euros now, mwah, the Harley just got through it here in the house

Anyway, the first step is often the drawing work

Then cut a batch

and paste

What's the difference with making tracks for a tank?

Tightening and holding on fragile things when I do this I use a very specialist clamp that I can adjust to press force, I work with purely simple tools but this was well worth the investment

Well, then you have a staircase that still needs to be sanded into shape, and that has to be done with care, because before you know it the ribs will shoot in every direction again

But perseverance wins and you still get something of this, still had to cut some loose and realign, but okay, for the time being these can harden for a while, then put the crossheads on and think about how they can be attached to the wing, movable of course

Well, I'll continue with the flaps, that's easy to write over, just CTRL C and CTRL V of the text, just different places

Vic Balshaw

Major General

Beautiful bit of workmanship.

- Thread starter

- #304

BertUS

Senior Airman

Thanks

Crimea_River

Marshal

Nice! And I like your clamp!.

- Thread starter

- #307

BertUS

Senior Airman

Thanks guys

Andy, I can sell your some, just 50 US dollar

Andy, I can sell your some, just 50 US dollar

Crimea_River

Marshal

No thanks! I have two but I don't use them as clamps!

Vic Balshaw

Major General

Same here, bit its an idea.

Good work so far!

- Thread starter

- #311

BertUS

Senior Airman

The flaps, I wrote that a simple CTRL C, CTRL V were sufficient, but in practice that turned out to be a lot more work. Now have a few days off so could continue, next to the animals, household, the motorcycle and so on.

Anyway, the flaps, I started with the inner ones first

There are a few openwork ribs, so with a house drawing and much more carving,

So I finally got this

And you have to put that together, nice and fragile work that you have to take the time for

After letting the glue harden a little longer, the rest was glued on and the shape sanded in

well and then the second

Well CTRL C, CTRL V so

https://modelbrouwers.nl/media/cache/83/58/83589108bc5c6b7801876e96ed78a51d.jpg[img]

Kind of the same story as above, how boring, but in the end, you have 2

[ATTACH=full]699732[/ATTACH]

Then the outer one, the first Mossies had 1 flap, but after extending the engine nacelle, these were divided (although I have to look for how to make that engine nacelle at the rear, there is not much to be found about it and what is there speaks sometimes against each other

Here's the inner one and the outer one in the basic shape

[ATTACH=full]699733[/ATTACH]

And with some fiddling you get these things, although they still have to be sanded neatly

[ATTACH=full]699734[/ATTACH]

And while I was looking at the drawing, I suddenly noticed that I had the ribs at the wrong angle on the inner flaps

so first like this

[img]https://modelbrouwers.nl/media/cache/2b/c8/2bc86286d79adb4213dbbe7f3b18ef76.jpg[img]

The ribs, run parallel to the two solid inner ones. But the drawing showed something different

[ATTACH=full]699735[/ATTACH]

Yep, they have to be loosened, converted and glued again

Well, it worked

And then also a photo with the parts already present to make the wings

[ATTACH=full]699736[/ATTACH]

So still h

Anyway, the flaps, I started with the inner ones first

There are a few openwork ribs, so with a house drawing and much more carving,

So I finally got this

And you have to put that together, nice and fragile work that you have to take the time for

After letting the glue harden a little longer, the rest was glued on and the shape sanded in

well and then the second

Well CTRL C, CTRL V so

https://modelbrouwers.nl/media/cache/83/58/83589108bc5c6b7801876e96ed78a51d.jpg[img]

Kind of the same story as above, how boring, but in the end, you have 2

[ATTACH=full]699732[/ATTACH]

Then the outer one, the first Mossies had 1 flap, but after extending the engine nacelle, these were divided (although I have to look for how to make that engine nacelle at the rear, there is not much to be found about it and what is there speaks sometimes against each other

Here's the inner one and the outer one in the basic shape

[ATTACH=full]699733[/ATTACH]

And with some fiddling you get these things, although they still have to be sanded neatly

[ATTACH=full]699734[/ATTACH]

And while I was looking at the drawing, I suddenly noticed that I had the ribs at the wrong angle on the inner flaps

so first like this

[img]https://modelbrouwers.nl/media/cache/2b/c8/2bc86286d79adb4213dbbe7f3b18ef76.jpg[img]

The ribs, run parallel to the two solid inner ones. But the drawing showed something different

[ATTACH=full]699735[/ATTACH]

Yep, they have to be loosened, converted and glued again

Well, it worked

And then also a photo with the parts already present to make the wings

[ATTACH=full]699736[/ATTACH]

So still h

Attachments

Last edited:

Vic Balshaw

Major General

From what has come through looks painstakingly good but the last 5 pics are not showing at my end.

- Thread starter

- #313

BertUS

Senior Airman

Vic, just like the whole project, I've to do things twice

EDIT

Huh, why they are now as attachtments, I overwrite the ATTATC line

EDIT

Huh, why they are now as attachtments, I overwrite the ATTATC line

Crimea_River

Marshal

Fiddly stuff but looks good.

Nicely done so far!

- Thread starter

- #317

BertUS

Senior Airman

So, best wishes for 2023, it's still allowed right?

I skipped a week because I played with Lego technic, which is quite addictive, but it is also an expensive side hobby, even if you get the sets from Marktplaats. Anyway, between visits to the ophthalmologist and such (so tomorrow I can go under the knife and hopefully I will see something normal again) I have done something, although I am not satisfied with everything and I am looking at how I can do that need to improve (it won't be me doing things over again)

So I continued with the wings and made the plates for the flaps, so the flaps turn along here, all photos are mss clearer than the previous sentence.

First the ribs

Then we stick a thin sheet of styrene against it with some overhang, where I already cut the holes

We repeat the same for the second

Now those pictures are there, but not really neat, so we will demolish and replace them as soon as I have prepared the installation of the flap control.

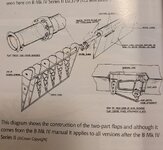

The flap control is hidden in the protruding point at the rear of the engine nacelle, the flaps are set in the chosen position by means of a hydraulic cylinder, so the controls are located on the right side of the main dashboard in front of the pilot and are operated with levers that are set in certain positions. set, so 15, 30 and 60 degrees down, if I'm right, I'm not a pilot.

Now it is a "easy" for the standard aircraft builders saw or cut the flaps loose from the wing and glue them in the desired angle, well, of course I have to make it much more difficult for myself

Judging from the sketch I understood the principle, but you also have to make it AND it has to be movable, so a lot of thinking about materials (printing would be the easiest, but that is very fragile with the resin I have now)

So first I made a sketch in SolidWorks to understand the principle.

[video=youtube]

View: http://youtube.com/watch?v=-FuMoKpQOEI%5B/video%5D

Ah, that makes it a bit clearer. Well first make those U-shaped pivots. I don't have any tube material, so first make rings yourself

So paste the pictures in a rough shape, so first square, then 8 angular, then 16 angular and then sand it smooth

And you get something like that with just a bit of pasting

Just loosen it up and you've got it

In the same way we also make the basic shape for the cylinder and we make a fixed pivot point for the torque, on the video that is the triangle

Lay down for a while

And we crochet everything together with pain and effort

Well, now I have to maken it nice and clear, add details en hopefully I can see better after the surgery

I skipped a week because I played with Lego technic, which is quite addictive, but it is also an expensive side hobby, even if you get the sets from Marktplaats. Anyway, between visits to the ophthalmologist and such (so tomorrow I can go under the knife and hopefully I will see something normal again) I have done something, although I am not satisfied with everything and I am looking at how I can do that need to improve (it won't be me doing things over again)

So I continued with the wings and made the plates for the flaps, so the flaps turn along here, all photos are mss clearer than the previous sentence.

First the ribs

Then we stick a thin sheet of styrene against it with some overhang, where I already cut the holes

We repeat the same for the second

Now those pictures are there, but not really neat, so we will demolish and replace them as soon as I have prepared the installation of the flap control.

The flap control is hidden in the protruding point at the rear of the engine nacelle, the flaps are set in the chosen position by means of a hydraulic cylinder, so the controls are located on the right side of the main dashboard in front of the pilot and are operated with levers that are set in certain positions. set, so 15, 30 and 60 degrees down, if I'm right, I'm not a pilot.

Now it is a "easy" for the standard aircraft builders saw or cut the flaps loose from the wing and glue them in the desired angle, well, of course I have to make it much more difficult for myself

Judging from the sketch I understood the principle, but you also have to make it AND it has to be movable, so a lot of thinking about materials (printing would be the easiest, but that is very fragile with the resin I have now)

So first I made a sketch in SolidWorks to understand the principle.

[video=youtube]

View: http://youtube.com/watch?v=-FuMoKpQOEI%5B/video%5D

Ah, that makes it a bit clearer. Well first make those U-shaped pivots. I don't have any tube material, so first make rings yourself

So paste the pictures in a rough shape, so first square, then 8 angular, then 16 angular and then sand it smooth

And you get something like that with just a bit of pasting

Just loosen it up and you've got it

In the same way we also make the basic shape for the cylinder and we make a fixed pivot point for the torque, on the video that is the triangle

Lay down for a while

And we crochet everything together with pain and effort

Well, now I have to maken it nice and clear, add details en hopefully I can see better after the surgery

Airframes

Benevolens Magister

Excellent !

You're really doing some fantastic work here.

You're really doing some fantastic work here.

- Thread starter

- #319

BertUS

Senior Airman

Thank you so much

Vic Balshaw

Major General

You lost me after the first pic, but then it twigged and I caught up. What amazing stuff your doing. Hope all goes well for tomorrow.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)