- Thread starter

- #481

Skyediamonds

Staff Sergeant

- 1,362

- May 26, 2018

The next series of steps will illustrate the fabrication and installation of the solenoid firing mechanism. This was part of my reason why I posted the question in my previous postings as to "... What is that silver colored object mounted on the right side?"

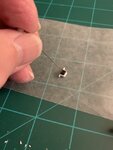

A plastic tubing was cut into a thin slice.

A black colored plastic strip was then cut and bent with a pair of tweezers into the first corner.

From there it was sized up to determine the remaining length and then cut. with an X-Acto # 11 blade

I purposely allowed my hands into the photo to help give scale to the small assembly

A plastic tubing was cut into a thin slice.

A black colored plastic strip was then cut and bent with a pair of tweezers into the first corner.

From there it was sized up to determine the remaining length and then cut. with an X-Acto # 11 blade

I purposely allowed my hands into the photo to help give scale to the small assembly