- Thread starter

- #341

Skyediamonds

Staff Sergeant

- 1,362

- May 26, 2018

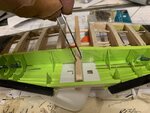

My initial thoughts were to use household wire. The type I found was relatively the size I was looking for. Plus, it bends very easy and retains that bend. I could shape it into complex patterns with ease. I also had plenty of this wire to do about four dozen wheel well interiors and then some. Just one itsy bitsy problem: Only needed to find a way to straighten it out. Upon unraveling the black colored wire, I tried every which way to straighten it out. I would cut a short length of wire, clamped one end to a vice and pulled it as straight as possible. Then I would roll it back and forth over a flat surface of the table. I came pretty close, but the kinks were still there no matter how much effort I put into it. Once the wire is bent, it would take an Act of Congress to get it straight. I had to figure out another way to simulate the plumbing.