- Thread starter

- #21

sounds good to me jjp.

i have a magazine article which might be of some use to you for this build, i'll scan it and post it on tuesday when i'm next off work

That would be awesome! Any extra info is always good!

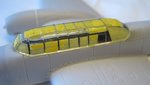

I indeed went with the Milliput option I mentioned earlier, seems like the best way to solve it the way I want it. So, I'll let the miliput set and cure for a bit and hopefully will be able to proceed with glueing the nose in place tomorrow. Some odds and end need looking into as far as the rest of the airframe is concerned, so I'll work on those in the mean time. [takes out masking tape and starts work on masking that big greenhouse on top...whooopie

]

]

Last edited: