- Thread starter

- #41

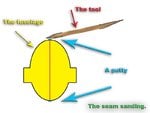

This is a little thing I decided to run to benefit the model. I have dry fitted the fuselages and tried to simulate glue with rubber bands and some finger pressue. Im hoping our expert seam / gap filler experts will be able to help me with suggestions so I can repair it precisely and not damage the detail. I have sanded out all the areas where it was attached to the spur mould and have gotten rid of all the flash. Im still doing the interior but thought I would post this up ASAP so I could give you guys some time to figure a solution.