N4521U

Colonel

Well...... out of the last repair I did on a 747 came this one from NZ. It's a bit more work than the other, not to mention twice the size!y postings on a collectors website. Works for me. Some hobby eh?

Starting with the wings.

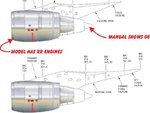

Two engines missing, one inboard, one outboard on the Port side. Difficulty is the starboard side had been broken off and remounted with two part epoxy, heavy! So the joins are kinda built up and a little off center. The short break on the inboard engine will have to be built up outwards a bit so I can cut the globs off the wings and get the engines to sit correctly. So I have to mold and cast each engine and fairing. The fairings are different.

Some cracks in and thru the wings, front to back, and along the length will have to be repaired. Broken off tips of some of the pointy things and some chips and crascks in the paint.

No horiz stabs on the tail, I will get fusey when wings are finished. I'll have to find a top scale view of the 747-300 and pattern the tail parts and make them from scratch.

Good news is, he haas a painter in NZ who can do the finish painting. This thing, like most is super glossy.

Work begins. Maybe I can get a new airbrush, if Wayne will give me the paticulars on the one he has. Hint hint.

Starting with the wings.

Two engines missing, one inboard, one outboard on the Port side. Difficulty is the starboard side had been broken off and remounted with two part epoxy, heavy! So the joins are kinda built up and a little off center. The short break on the inboard engine will have to be built up outwards a bit so I can cut the globs off the wings and get the engines to sit correctly. So I have to mold and cast each engine and fairing. The fairings are different.

Some cracks in and thru the wings, front to back, and along the length will have to be repaired. Broken off tips of some of the pointy things and some chips and crascks in the paint.

No horiz stabs on the tail, I will get fusey when wings are finished. I'll have to find a top scale view of the 747-300 and pattern the tail parts and make them from scratch.

Good news is, he haas a painter in NZ who can do the finish painting. This thing, like most is super glossy.

Work begins. Maybe I can get a new airbrush, if Wayne will give me the paticulars on the one he has. Hint hint.

Attachments

Last edited: