- Thread starter

- #41

parsifal

Colonel

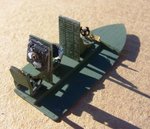

Here are the shots of the scratch built compass gimbal and the CP "black boxes" i built and fitted last night. The cockpit is ready for installation and the fuselage can then be buttoned up

as always, these extreme close ups really brutalize the work, but at normal magnificaton the scratch building looks quite good. im happy

as always, these extreme close ups really brutalize the work, but at normal magnificaton the scratch building looks quite good. im happy